Difference between revisions of "Groundwater Sampling - No-Purge/Passive"

m (1 revision imported) |

m |

||

| Line 7: | Line 7: | ||

| − | '''CONTRIBUTOR(S):''' [[Dr. David Adamson, P.E.]] and [[Dr. Thomas McHugh]] | + | '''CONTRIBUTOR(S):''' [[Dr. David Adamson, P.E. | David Adamson]] and [[Dr. Thomas McHugh | Thomas McHugh]] |

Revision as of 17:40, 20 June 2018

No-purge and passive sampling methods eliminate the pre-purging step for groundwater sample collection and represent alternatives to conventional sampling methods that rely on low-flow purging of a well prior to collection. These methods tend to be more efficient than conventional sampling methods, hence representing a possible lower-cost alternative. Common types of no-purge/passive sampling methods include grab samplers, equilibrium (or diffusion) samplers, and sorptive samplers[1]. Performance studies show little-to-no bias in the average results obtained using no-purge and passive sampling relative to low-flow sampling results. These methods have also been validated for several different types of compounds (primarily volatile organics)[2]. However, there can be a consistent difference in the results obtained using low-flow vs. no-purge sampling methods for some individual monitoring wells[3]. Low-flow purging tends to produce flow-weighted average concentrations while results from passive samplers may reflect depth-discrete concentrations, but this can be influenced by factors such as in-well mixing.

Related Article(s):

CONTRIBUTOR(S): David Adamson and Thomas McHugh

Key Resource(s):

- Protocol for use of five passive samplers to sample for a variety of contaminants in groundwater[2]

- Technology overview of passive sampler technologies[4]

Introduction

No-purge and passive sampling refer to several “non-traditional” methods for collecting groundwater samples from a monitoring well for the purposes of site characterization or long-term monitoring. In some cases, the terms are applied to the physical devices used to collect the samples (e.g., passive samplers). These methods are an alternative to traditional sampling which involves purging and disposal of groundwater from a well prior to collecting the sample for analysis. No-purge and passive sampling methods eliminate the purging step from the sample collection process.

The terms “no-purge sampling” and “passive sampling” are often used interchangeably, but there are differences. No-purge sampling includes any method where no water is removed (i.e., purged) from the well prior to sample collection. The sample itself can be collected with a pump and still be considered a “no-purge” sample. Passive sampling includes any method where a device is placed in a well and the sample enters that device without the use of a pump or other mechanical action. All passive sampling methods are no-purge sampling methods, but not all no-purge sampling can be considered passive sampling.

Types

There are a variety of sampling methods that can be considered no-purge or passive. A common feature is that all involve the collection of groundwater from a discrete portion of the screened interval of a well. Here are some examples:

- Grab Samplers: These sampling devices are installed at a desired depth. A sample is collected by “grabbing” water when the device is activated or triggered from the ground surface. Collection time is generally short (seconds) even though deployment in the well (prior to sample collection) may be long (weeks to months). Commercially-available examples include the Snap SamplerTM (Fig. 1) and HydraSleeveTM[4][2], although the latter is slightly different because it collects a sample over a pull distance of 3-5 feet (i.e., the distance covered when the device is pulled).

- Equilibrium or Diffusion Samplers: Sampling devices that are installed in a well and then allowed to come to equilibrium with the groundwater in it (Fig. 2). Diffusion of contaminants occurs across a barrier that separates the well water and the interior of the sampler, such that the concentration in the sampler will equal the concentration in the well after equilibrium is reached. This process generally takes a few weeks (depending on the contaminant diffusion rate) and thus dictating the time that the devices are deployed in the well prior to sample collection. These samplers are effective for measuring chlorinated solvents and other volatile compounds, but are less effective for contaminants that do not readily diffuse (e.g., inorganics, metals) or those that are hydrophilic (e.g., methyl tert-butyl ether (MTBE), 1,4-dioxane) or not particularly volatile (e.g., polychlorinated biphenyl (PCBs)). The passive diffusion bag (PDB) is the most common type of equilibrium sampler and is relatively simple in design[4]; more robust devices such as the regenerated cellulose dialysis membrane (RCDM) sampler also exist[4][2].

- Sorptive Samplers: Samplers that rely on the accumulation of organic contaminants in groundwater onto a separate medium that is contained within the sampler[5]. This is typically via sorption onto a solid medium like activated carbon, but they can also use partitioning into an organic solvent. Regardless, these samplers accumulate contaminant mass over time, and this mass can be converted to a concentration based on the time the sampler has been deployed (typically hours to days). As a result, the estimated concentration is actually a time-weighted average concentration over the period of exposure.

Comparison with Conventional Sampling

Effects of Eliminating Purging

In groundwater monitoring, it is the groundwater contaminant concentration in the formation adjacent to a monitoring well that is of interest. Therefore, traditional methods for groundwater sampling have relied on purging to remove the “stagnant” water from the well to ensure that formation water is being sampled[6]. However, it is important to remember that the well can be considered in dynamic equilibrium with the groundwater in the adjacent formation. Groundwater flows through the screened interval of the monitoring well due to hydrostatic pressure, resulting in continuous flushing of the screened interval within the well with groundwater from the formation. Furthermore, in-well mixing driven by pressure or salinity gradients may homogenize the groundwater within the well. This lessens the concern that water in the monitoring well, the water that is collected using a no-purge or passive method, would not be representative of the formation.

However, there are other reasons why a groundwater sample collected using a no-purge/passive method could be different than a sample collected using low-flow purging. For example, mixing may occur infrequently in some monitoring wells, such that the passive sampler is collecting more of a depth-discrete sample relative to a low-flow sample, which is typically assumed to represent a flow-weighted average across the screened interval (i.e., higher permeability zones contribute more flow). Furthermore, research demonstrates that concentrations can fluctuate widely during pumping based on the location of the pump intake relative to higher concentration sub-intervals within the screened interval[7]. In other words, there may be a transient period before the flow-weighted average is obtained, which could contribute to differences between a low-flow sample and a sample collected using passive methods.

Installation and Retrieval

Sampling device installation far in advance of sample collection is a main difference between passive sampling methods and traditional sampling methods. Passive samplers are frequently weighted to overcome buoyancy, and then lowered into the well until they reach the desired depth within the screened interval. The line used to lower the sampler is then secured to the well head or other fixed surface point. The sampler is retrieved following a pre-specified period of deployment that corresponds to either the time required for equilibrium to occur (i.e., equilibrium samplers) or the time between monitoring events. Transfer to a different sampling container (e.g., 40-mL VOA vial) may be necessary for some samplers (e.g., passive diffusion bags). In many cases, the sampler for the next monitoring event is installed when the sampler for the current monitoring event is complete. This procedure eliminates the need for an extra trip and causes mobilization requirements to be comparable to conventional sampling.

Cost

Passive samplers and other no-purge methods are typically adopted to reduce costs associated with long-term monitoring. Primary drivers for cost savings are: 1) reduction in labor hours associated with collecting the sample and 2) elimination of costs associated with handling and disposal of purge water. Cost savings will vary depending on the type of sampling method and the scope of the sampling program, but reductions of 10-70% relative to low-flow purging have been reported in demonstration studies[1].

Performance

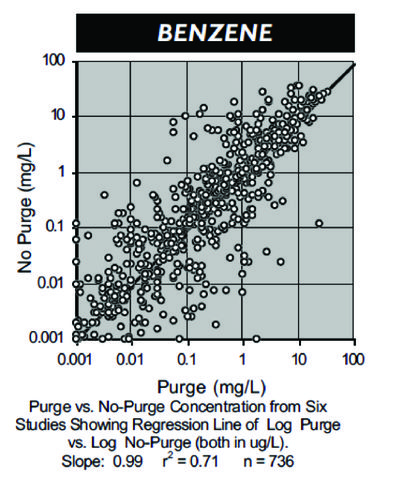

Empirical studies determined that no-purge sampling generated concentration results comparable to those obtained using more conventional methods. Six separate no-purge studies from hydrocarbon sites were reviewed with these key conclusions[8]:

“…samples collected after standard well purging do not systematically have higher contaminant concentrations…there is a high probability that on average, unpurged sample concentrations exceed purged sample concentrations.” (Study 1, California RWQCB, Region 8 Orange County Health Care Agency/Unocal)

“No-purge sampling methodology will not affect the overall variability in chemical data, and will provide a comparable, and in many cases more conservative estimate of petroleum hydrocarbons in groundwater.” (Study 2, Western States Petroleum Association)

“No purging is recommended for routine sampling, while purging is recommended when a critical decision is to be made (i.e., no further action or closure).” (Study 3, Shell Oil and EnviroTrac:Three-State Study)

“…within a 99% confidence interval, there was no significant difference between concentrations in samples collected without well purging to samples collected after well purging.” (Study 4, Shell Oil and EnviroTrac:New York Study)

“Clearly, if one were to estimate the location of the contaminant plume, or the magnitude of the BTEX concentration at any specific point there would not be a significant difference if these estimates were based upon the pre-purge rather than the post-purge values.” (Study 5, University of Massachusetts: Dartmouth Study)

“…the practice of purging prior to sampling for testing does not appear to have strong justification in the environmental situations that are represented at least by the standard wells.” (Study 6, BP Amoco: Maryland Study)

Figure 3 shows a comparison of purge vs. no-purge data from these six studies.

There have been recent efforts aimed at examining and/or validating the use of various types of passive samplers for groundwater monitoring. These include the following:

- ITRC: The Interstate Technology and Regulatory Council (ITRC) published a series of guidance documents that provides descriptions of many commercially-available devices, results of validation studies completed to-date, and protocols for their use[9][4][2]. This guidance helped facilitate the regulatory acceptance of passive sampling methods, although their use in long-term monitoring programs is typically approved on a case-by-case basis[2].

- ESTCP demonstration projects: Several projects have successfully demonstrated that passive samplers can generate concentration results similar to those obtained using low-flow purging. This includes Snap SamplersTM[10][11], a sorptive-style sampler called the AGI Universal Sampler[5], and the RCDM equilibrium sampler[12][13].

- ESTCP study on monitoring variability: Several variations on sample collection were tested at three sites. The collective data confirmed that Snap Samplers provided equivalent results to low-flow purging, while a low bias and higher event-to-event variability was observed with the HydraSleeveTM system for some wells[14][15].

Selecting Groundwater Sampling - No-Purge/Passive Methods

Passive sampling methods, and passive diffusion bags in particular, have widespread regulatory support for long-term monitoring purposes and can rely on extensive published guidance [4]. However, for any site that is considering adopting these methods, a site-specific validation study may be valuable or even required for regulatory approval.

It is important to know that there are certain limitations that may make no-purge or passive sampling inappropriate at some sites. Stroo et al. (2014)[1] highlighted five specific limitations for passive samplers:

- Some passive samplers cannot be used for all analytes.

- Some passive samplers may not be able to collect sufficient sample volume for all required analyses.

- Some passive samplers may not fit into wells smaller than the common 2-inch diameter well.

- Some devices are not appropriate for “total” or unfiltered sample analysis because of diffusive filtration.

- Some methods (i.e., sorptive methods) produced a calculated concentration rather than a measured concentration.

Summary

At most sites, no-purge/passive groundwater sampling data are comparable to monitoring data from conventional purge-based sampling methods. The most appropriate method should be selected based on considerations of implementability and cost. Many no-purge methods show little or no bias compared to low flow methods compared over many samples over many wells. However, for an individual monitoring well, changing the sample method may result in an increase or a decrease in measured contaminant concentration. Therefore, the effect of changing sampling methods should be considered with evaluating any long-term concentration trend.

References

- ^ 1.0 1.1 1.2 Stroo, H., R.H. Anderson, and A. Leeson, 2014. Passive Sampling for Groundwater Monitoring Technology Status. Prepared for Strategic Environmental Research and Development Program (SERDP) and the Environmental Security Technology Certification Program (ESTCP), Arlington, VA. Guidance Document

- ^ 2.0 2.1 2.2 2.3 2.4 2.5 ITRC, 2007. Protocol for use of five passive samplers to sample for a variety of contaminants in groundwater., Washington, D.C., Interstate Technology and Regulatory Council, Diffusion Sampler Team. Report pdf

- ^ Kulkarni, P.R., Krebs, C.J., Britt, S., Newell, C.J., McHugh, T.E., in review. Effect of groundwater sampling methods on short-term variability and concentration bias: two field sites.

- ^ 4.0 4.1 4.2 4.3 4.4 4.5 ITRC, 2006. Technology overview of passive sampler technologies. Washington, D.C., Interstate Technology and Regulatory Council, Diffusion Sampler Team. Report pdf

- ^ 5.0 5.1 Parker, L., Willey, R., McHale, T., Major, W., Hall, T., Bailey, R., Gagnon, K. and Gooch, G., 2014. Demonstration of the AGI universal samplers (FKA the GORE (registered trademark) modules) for passive sampling of hroundwater. Environmental Security Technology Certification Program, Arlington, VA. ER-200921

- ^ Barcelona, M.J., Varljen, M.D., Puls, R.W. and Kaminski, D., 2005. Ground water purging and sampling methods: History vs. hysteria. Groundwater Monitoring & Remediation, 25(1), pp.52-62. doi: 10.1111/j.1745-6592.2005.0001.x

- ^ Britt, S., Martin-Hayden, J. and Plummer, M.A., 2014. An assessment of aquifer/well flow dynamics: identification of parameters key to passive sampling and application of downhole sensor technologies. Strategic Environmental Research and Development Program, Arlington, VA. ER-1704

- ^ 8.0 8.1 Newell, C.J., Lee, R.S. and Spexet, A.H., 2000. Groundwater Services Inc. 2000. No-Purge Groundwater Sampling: an Approach for Long-Term Monitoring. American Petroleum Institute Summary of Research Results (12). Report pdf

- ^ ITRC, 2004. Technical and regulatory guidance for using polyethylene diffusion bag samplers to monitor volatile organic compounds in groundwater. Washington, D.C., Interstate Technology and Regulatory Council, Diffusion Sampler Team. Report pdf

- ^ Parker, L., Mulherin, N., Gooch, G., Major, W., Willey, R., Imbrigiotta, T., Gibs, J. and Gronstal, D., 2009. Demonstration/validation of the snap sampler passive ground water sampling device. Environmental Security Technology Certification Program, ER-200630. ER-200630

- ^ Britt, S.L., Parker, B.L. and Cherry, J.A., 2010. A downhole passive sampling system to avoid bias and error from groundwater sample handling. Environmental Science & Technology, 44(13), pp.4917-4923. doi: 10.1021/es100828u

- ^ Imbrigiotta, T.E., Trotsky, J.S. and Place, M.C., 2007. Demonstration and validation of a regenerated cellulose dialysis membrane diffusion sampler for monitoring ground water quality and remediation progress at DoD sites. Environmental Security Technology Certification Program, ER-200313. ER-200313

- ^ Imbrigiotta, T.E., Trotsky, J.S., 2011. Demonstration and validation of a regenerated cellulose dialysis membrane diffusion sampler for monitoring groundwater quality and remediation progress at DoD sites: Perchlorate and Ordnance Compounds. Environmental Security Technology Certification Program, ER-200313. ER-200313

- ^ McHugh, T.E., Kulkarni, P.R., Beckley, L.M., Newell, C.J. and Zumbro, M., 2015. Negative bias and increased variability in VOC concentrations using the HydraSleeve in monitoring wells. Groundwater Monitoring & Remediation, 36, 79–87. doi: 10.1111/gwmr.12141

- ^ Kulkarni, P.R., Newell, C.J., Krebs, C., and McHugh, T.E., 2016. Methods for minimization and management of variability in long-term groundwater monitoring results. Environmental Security Technology Certification Program, ER-201209. ER-201209