Difference between revisions of "Perfluoroalkyl and Polyfluoroalkyl Substances (PFAS)"

m (→Introduction) |

|||

| Line 13: | Line 13: | ||

==Introduction== | ==Introduction== | ||

| − | PFAS were first developed in the 1940s and have been used by numerous industrial and commercial sectors for products that benefited from PFAS’ unique properties, including thermal and chemical stability, water resistance, stain resistance, and their surfactant nature. Awareness of PFAS in the environment first emerged in the late 1990s following developments in analytical instrumentation which enhanced detection of ionized substances such as PFAS<ref>Hansen, K.J., L.A. Clemen, M.E. Ellefson and H.O. Johnson, 2001. Compound-Specific, Quantitative Characterization of Organic Fluorochemicals in Biological Matrices. Environmental Science and Technology 35(4):766-770.</ref>. This environmental awareness was generally concurrent to increased scrutiny into the health effects of PFAS<ref>U.S. Environmental Protection Agency, 2018. Risk Management for Per- and Polyfluoroalkyl Substances (PFASs) under TSCA. https://www.epa.gov/assessing-and-managing-chemicals-under-tsca/risk-management-and-polyfluoroalkyl-substances-pfass</ref>. In 2000, the sole U.S. manufacturer of PFOS voluntarily discontinued production<ref>U.S. Environmental Protection Agency, 2000. EPA and 3M announce phase out of PFOS. News release dated Tuesday May 16. [https://yosemite.epa.gov/opa/admpress.nsf/0/33aa946e6cb11f35852568e1005246b4 U.S. EPA PFOS Phase Out Announcement]</ref>. Shortly thereafter, legal actions were taken against PFAS product manufacturing facilities in the Ohio River Valley in West Virginia<ref>Rich, N., 2016. The lawyer who became DuPont’s worst nightmare. The New York Times Magazine.</ref>. Between 2006 and 2015, in cooperation with the EPA, eight global companies with PFAS-related operations voluntarily phased out the manufacture of PFOA and similarly structured PFAS with longer carbon chains<ref>U.S. Environmental Protection Agency, 2018. Fact Sheet: 2010/2015 PFOA Stewardship Program. https://www.epa.gov/assessing-and-managing-chemicals-under-tsca/fact-sheet-20102015-pfoa-stewardship-program</ref>. In 2011, recognizing the potential impact of PFAS for the Department of Defense due to the military’s ubiquitous use of PFAS-containing AFFF, SERDP/ESTCP research programs began funding PFAS-related research, and the U.S. Air Force began conducting initial site investigations at former fire-fighting training areas<ref>SERDP/ESTCP website on Per- and Polyfluorinated Substances (PFASs). https://www.serdp-estcp.org/Featured-Initiatives/Per-and-Polyfluoroalkyl-Substances-PFASs</ref>. The U.S. Environmental Protection Agency (EPA) issued provisional drinking water health advisories for PFOA and PFOS in 2009 and replaced these with more stringent health advisories in 2016<ref>U.S. Environmental Protection Agency, 2016. Drinking water health advisories for PFOA and PFOS. [https://www.epa.gov/ground-water-and-drinking-water/drinking-water-health-advisories-pfoa-and-pfos U.S. EPA Water Health Advisories - PFOA and PFOS]</ref>. Over the past five years, regulating agencies in several states have issued screening levels, notification levels, and health-based guidelines for PFOS, PFOA and other PFAS. Several states have undertaken statewide sampling programs of drinking water systems and groundwater resources in the vicinity of potential source areas including manufacturing facilities, military fire-training facilities, airports, refineries, and landfills<ref>California State Water Resources Control Board, 2019. PFAS Phased Investigation Approach. https://www.waterboards.ca.gov/pfas/docs/7_investigation_plan.pdf</ref><ref>Michigan, 2019. PFAS response. Taking Action, Protecting Michigan. Michigan PFAS Action Response Team (MPART).</ref>. | + | PFAS were first developed in the 1940s and have been used by numerous industrial and commercial sectors for products that benefited from PFAS’ unique properties, including thermal and chemical stability, water resistance, stain resistance, and their surfactant nature. Awareness of PFAS in the environment first emerged in the late 1990s following developments in analytical instrumentation which enhanced detection of ionized substances such as PFAS<ref>Hansen, K.J., L.A. Clemen, M.E. Ellefson and H.O. Johnson, 2001. Compound-Specific, Quantitative Characterization of Organic Fluorochemicals in Biological Matrices. Environmental Science and Technology 35(4):766-770.</ref>. This environmental awareness was generally concurrent to increased scrutiny into the health effects of PFAS<ref>U.S. Environmental Protection Agency, 2018. Risk Management for Per- and Polyfluoroalkyl Substances (PFASs) under TSCA. https://www.epa.gov/assessing-and-managing-chemicals-under-tsca/risk-management-and-polyfluoroalkyl-substances-pfass</ref>. In 2000, the sole U.S. manufacturer of PFOS voluntarily discontinued production<ref>U.S. Environmental Protection Agency, 2000. EPA and 3M announce phase out of PFOS. News release dated Tuesday May 16. [https://yosemite.epa.gov/opa/admpress.nsf/0/33aa946e6cb11f35852568e1005246b4 U.S. EPA PFOS Phase Out Announcement]</ref>. Shortly thereafter, legal actions were taken against PFAS product manufacturing facilities in the Ohio River Valley in West Virginia<ref>Rich, N., 2016. The lawyer who became DuPont’s worst nightmare. The New York Times Magazine.</ref>. Between 2006 and 2015, in cooperation with the EPA, eight global companies with PFAS-related operations voluntarily phased out the manufacture of PFOA and similarly structured PFAS with longer carbon chains<ref>U.S. Environmental Protection Agency, 2018. Fact Sheet: 2010/2015 PFOA Stewardship Program. https://www.epa.gov/assessing-and-managing-chemicals-under-tsca/fact-sheet-20102015-pfoa-stewardship-program</ref>. In 2011, recognizing the potential impact of PFAS for the Department of Defense due to the military’s ubiquitous use of PFAS-containing AFFF, SERDP/ESTCP research programs began funding PFAS-related research, and the U.S. Air Force began conducting initial site investigations at former fire-fighting training areas<ref>SERDP/ESTCP website on Per- and Polyfluorinated Substances (PFASs). https://www.serdp-estcp.org/Featured-Initiatives/Per-and-Polyfluoroalkyl-Substances-PFASs</ref>. The U.S. Environmental Protection Agency (EPA) issued provisional drinking water health advisories for PFOA and PFOS in 2009 and replaced these with more stringent health advisories in 2016<ref name="USEPA2016">U.S. Environmental Protection Agency, 2016. Drinking water health advisories for PFOA and PFOS. [https://www.epa.gov/ground-water-and-drinking-water/drinking-water-health-advisories-pfoa-and-pfos U.S. EPA Water Health Advisories - PFOA and PFOS]</ref>. Over the past five years, regulating agencies in several states have issued screening levels, notification levels, and health-based guidelines for PFOS, PFOA and other PFAS. Several states have undertaken statewide sampling programs of drinking water systems and groundwater resources in the vicinity of potential source areas including manufacturing facilities, military fire-training facilities, airports, refineries, and landfills<ref>California State Water Resources Control Board, 2019. PFAS Phased Investigation Approach. https://www.waterboards.ca.gov/pfas/docs/7_investigation_plan.pdf</ref><ref>Michigan, 2019. PFAS response. Taking Action, Protecting Michigan. Michigan PFAS Action Response Team (MPART).</ref>. |

==Nomenclature== | ==Nomenclature== | ||

Revision as of 16:00, 30 October 2019

Perfluoroalkyl and polyfluoroalkyl substances (PFAS) are a class of man-made chemicals suspected to cause adverse human and ecological health effects. The acronym “PFAS” comprises thousands of individual compounds; the two most studied and regulated are perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS). PFAS, including PFOA and PFOS, have entered the environment from a variety of sources and release scenarios, including releases from manufacturing facilities and areas where aqueous film-forming foam (AFFF), a type of fire-fighting foam, was applied. Many PFAS have unique physical and chemical properties that render them highly stable and resistant to degradation in the environment. They are typically removed from water supplies using granular activated carbon or ion exchange resins, although research is ongoing to develop in situ treatment technologies and more cost-effective ex situ treatment methods.

Contents

- 1 Introduction

- 2 Nomenclature

- 3 Physical and Chemical Properties

- 4 Environmental Concern

- 5 Uses and Potential Sources to the Environment

- 6 Regulation

- 7 Sampling and Analytical Methods

- 8 Fate and Transport

- 9 Soil and Groundwater Remediation

- 10 PFAS Treatment Research

- 11 Summary

- 12 References

- 13 See Also

Related Article(s):

CONTRIBUTOR(S): Dr. Rula Deeb, Dr. Jennifer Field, Elisabeth Hawley, and Dr. Christopher Higgins

Key Resource(s):

Introduction

PFAS were first developed in the 1940s and have been used by numerous industrial and commercial sectors for products that benefited from PFAS’ unique properties, including thermal and chemical stability, water resistance, stain resistance, and their surfactant nature. Awareness of PFAS in the environment first emerged in the late 1990s following developments in analytical instrumentation which enhanced detection of ionized substances such as PFAS[2]. This environmental awareness was generally concurrent to increased scrutiny into the health effects of PFAS[3]. In 2000, the sole U.S. manufacturer of PFOS voluntarily discontinued production[4]. Shortly thereafter, legal actions were taken against PFAS product manufacturing facilities in the Ohio River Valley in West Virginia[5]. Between 2006 and 2015, in cooperation with the EPA, eight global companies with PFAS-related operations voluntarily phased out the manufacture of PFOA and similarly structured PFAS with longer carbon chains[6]. In 2011, recognizing the potential impact of PFAS for the Department of Defense due to the military’s ubiquitous use of PFAS-containing AFFF, SERDP/ESTCP research programs began funding PFAS-related research, and the U.S. Air Force began conducting initial site investigations at former fire-fighting training areas[7]. The U.S. Environmental Protection Agency (EPA) issued provisional drinking water health advisories for PFOA and PFOS in 2009 and replaced these with more stringent health advisories in 2016[8]. Over the past five years, regulating agencies in several states have issued screening levels, notification levels, and health-based guidelines for PFOS, PFOA and other PFAS. Several states have undertaken statewide sampling programs of drinking water systems and groundwater resources in the vicinity of potential source areas including manufacturing facilities, military fire-training facilities, airports, refineries, and landfills[9][10].

Nomenclature

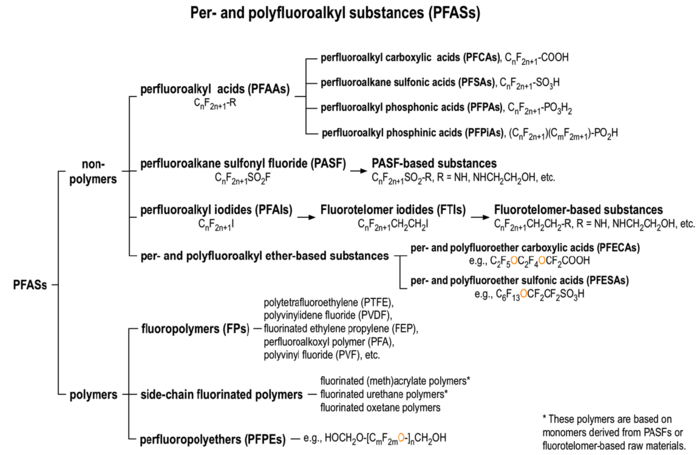

There are over 3,000 PFAS currently on the global market. A summary of families of compounds that are included in the umbrella terminology “PFAS” is provided in Figure 1[11]. Perfluoroalkyl compounds have a non-polar hydrophobic carbon (alkyl) chain structure that is fully saturated with fluorine atoms (i.e., they are perfluoroalkyl substances) attached to a hydrophilic polar functional group. Polyfluoroalkyl compounds have a similar structure but have at least one carbon that is bound to hydrogen rather than fluorine (Figure 2). Carbon chains may be linear or branched, leading to a variety of isomers. The term PFAS also includes fluoropolymers that may consist of thousands of shorter-chain units bonded together[12].

One of the most studied and regulated families of perfluoroalkyl compounds are the perfluoroalkyl acids (PFAAs), which include perfluoroalkyl carboxylic acids (PFCAs) and perfluoroalkyl sulfonic acids (PFSAs). PFOA, a perfluoroalkyl carboxylic acid, and PFOS, a perfluoroalkyl sulfonic acid, are both PFAAs with eight carbons. Other PFCAs with the number of carbons ranging from nine to four include perfluorononanoic acid (PFNA), perfluoroheptanoic acid (PFHpA), perfluorohexanoic acid (PFHxA), and perfluorobutanoic acid (PFBA). PFAAs are sometimes differentiated as “long-chain” or “short-chain.” The term “long-chain” refers to PFCAs with eight or more carbons and PFSAs with six or more carbons. The term “short-chain” refers to PFCAs with seven or fewer carbons and PFSAs with five or fewer carbons[12].

Physical and Chemical Properties

| Property | PFOS (Free Acid) | PFOA (Free Acid) |

|---|---|---|

| Chemical Abstracts Service Number | 1763-23-1 | 335-67-1 |

| Physical State (at 25° C and 1 atmosphere pressure) | White powder | White powder/waxy white solid |

| Molecular weight (g/mol) | 500 | 414 |

| Water solubility at 25° C (mg/L) | 680 | 9,500a |

| Melting point (°C) | No data | 45 to 54 |

| Boiling point (°C) | 258 to 260 | 188 to 192 |

| Vapor pressure at 20° C (mm Hg) | 0.002 | 0.525 to 10 |

| Organic-carbon partition coefficient (log Koc) | 2.4 to 3.7 | 1.89 to 2.63 |

| Henry’s Law constant (atm-m3/mol) | Not measurable | 3.57x10-6 |

| Half-life | Atmospheric: 114 days Water: >41 years (at 25° C) Human: 3.1 to 7.4 years |

Atmospheric: 90 daysb Water: >92 years (at 25° C) Human: 2.1 to 8.5 years |

| Abbreviations: g/mol = grams per mole; mg/L = milligrams per liter; °C = degrees Celsius; mm Hg = millimeters of mercury; atm-m3/mol = atmosphere-cubic meters per mole. | ||

| Notes: a Solubility in purified water. b The atmospheric half-life value for PFOA was extrapolated from available data measured over short study periods. | ||

The combination of the polar and non-polar structure makes PFAAs “amphiphilic,” associating with both water and oils, while the strength of their carbon-fluorine bonds lends them extremely high chemical and thermal stabilities. In most groundwater and surface water environments, PFAAs are found as the water-soluble anionic (i.e. deprotonated, negatively charged) form. Other groups of PFAS can be cationic (positively charged) or zwitterionic (possessing both a positive and negative charge) under typical environmental conditions. In general, documented physical properties of PFAS are scarce, and much that is available for PFAAs is related to the acid forms of the compounds, which are not typically found in the environment[12]. The surfactant properties of PFAAs complicate the prediction of their physiochemical properties, such as vapor pressure and partitioning coefficients. Relevant properties of PFOS and PFOA are summarized below in Table 1. A summary of the general characteristics of PFAS has been compiled in Table 6-2 of the ITRC fact sheet on PFAS naming conventions and physical and chemical properties[12].

Environmental Concern

Environmental concern surrounding PFAS stems from their widespread detection, high degree of environmental stability and mobility, and suspected toxicological effects on humans and the environment. Perfluorinated compounds, including PFAAs, are very stable and do not biodegrade. As a result these compounds are found throughout the global environment. Trace amounts of perfluorinated compounds have been detected at remote locations like the Arctic, far from potential point sources[16]. Other studies have shown that some long-chain perfluorinated substances bioaccumulate and biomagnify in wildlife[17]. Because of this, higher trophic wildlife including fish and birds, and humans who consume them, can be particularly susceptible to any deleterious health effects posed by PFAS[18]. The Dutch National Institute for Public Health and the Environment calculated a maximum permissible concentration for PFOS of 0.65 nanograms per liter (ng/L) for fresh water, based on human consumption of fish[1]. Recent fish and wildlife consumption advisories have been issued at certain locations in the United States associated with PFAS contamination[19][20]

Like other aspects of PFAS research, information on the toxicological effects of PFAS on humans is still emerging. PFOA and PFOS have half-lives of 2.1-8.5 years and 3.1-7.4 years, respectively, in humans[15]. PFAS typically accumulate in the liver, proteins, and the blood stream[13]. Toxicological and epidemiological studies of PFOA, PFOS and other PFAAs indicate potential association with a constellation of ailments including decreased fertility, increased cholesterol, suppression of response to vaccines, and certain cancers[15][21]. Both PFOA and PFOS are suspected carcinogens, but their carcinogenicity remains to be classified by the U.S. EPA[13]. The International Agency for Research on Cancer (IARC) has classified PFOA as a Group 2B carcinogen, i.e., possibly carcinogenic to humans[22][23]. The U.S. EPA published draft oral reference doses of 20 ng/kg-day for both PFOA and PFOS (based on non-cancer hazard)[13]. Drinking water ingestion, fish consumption, dermal contact with water, and (accidental) ingestion of or contact with contaminated soil are the exposure pathways of concern with respect to human health.

Uses and Potential Sources to the Environment

Due to their unique properties, including surfactant qualities, heat and stain resistance, and amphiphilic nature, PFAS are used widely by a number of industries, including carpet, textile and leather production, chromium plating, photography, photolithography, paper products, semi-conductor manufacturing, coating additives, and cleaning products[24][25]. Sources to the environment include primary manufacturing facilities, where PFAS is produced, and secondary manufacturing facilities, where PFAS is incorporated into products. PFAS are found in a variety of consumer products including food paper and packaging, furnishings, waterproof clothing, and cosmetics[26]. The presence of PFAS in consumer products has created an urban background concentration in stormwater, wastewater treatment plant influent[27], and landfill leachate[28].

An additional widely documented source of PFAS is AFFF. AFFF is as a Class B firefighting foam used to combat flammable liquid fires. AFFF was released in large quantities at firefighting training areas as part of routine handling, fire-suppression training and equipment testing, and during fire emergency responses. While all AFFF contains PFAS[29], the types and concentrations of PFAS in AFFF vary among manufacturers and manufacturing time periods. 3M AFFF products were made using an electrochemical fluorination process that produced a high percentage of PFAS as PFOS, while other formulations were made using a telomerization process and contain a different suite of PFAS.

Regulation

Final regulations have not yet been promulgated for PFAS; current criteria for PFAS are typically in the form of guidance or advisory levels (Table 2). The U.S. EPA recently developed Drinking Water Health Advisory levels for PFOA and PFOS, replacing previously published provisional values. Several states including Minnesota, Maine and New Jersey, have published screening values or interim criteria for one or more PFAS including PFOS, PFOA, perfluorobutanesulfonic acid (PFBS), perfluorobutanoic acid (PFBA) and perfluorononanoic acid (PFNA) (Table 2). Drinking water, groundwater, and soil criteria in the European Union was recently published in a summary report[30].

Other regulatory actions have restricted the use and production of PFAS. PFOS was added to list of chemicals under the Stockholm Convention on persistent organic pollutants in 2009. Nearly all use of PFOS is therefore banned in Europe, with some exemptions. Substances or mixtures may not contain PFOS above 0.001% by weight (EU 757/2010). In the U.S., because PFOS manufacturing was voluntarily phased out in 2002, AFFF containing PFOS is no longer manufactured. The U.S. military and others still have large quantities of stockpiled AFFF containing PFOS, although its use is discouraged.

| REGULATORY AGENCY | DESCRIPTION | PFOS | PFOA | PFBS | PFBA | PFNA | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DRINKING WATER (µg/L) | |||||||||||

| U.S. EPA | Drinking Water Health Advisories | 0.07 | 0.07 | ||||||||

| Health Canada | Drinking Water Screening Values | 0.6 | 0.2 | 15 | 30 | 0.2 | |||||

| Maine Department of Environmental Protection | Maximum Exposure Guideline | 0.1 | |||||||||

| Michigan Department of Environmental Quality | Drinking Water Surface Water Quality Value | 0.011 | 0.42 | ||||||||

| New Jersey Department of Environmental Protection | Preliminary Health-Based Guidance Value | 0.04 | |||||||||

| New Jersey Department of Environmental Protection | Development of MCL Recommendations for PFOA and PFOS are Currently in Progress | 0.04 | |||||||||

| New Jersey Department of Environmental Protection | Health-Based Maximum Contaminant Level (MCL) Recommendation | 0.013 | |||||||||

| Vermont Department of Health | Drinking Water Health Advisory Level | 0.02 | |||||||||

| GROUNDWATER (µg/L) | |||||||||||

| Minnesota Department of Health | Health Risk Limit for Groundwater | 0.3 | 0.3 | 7 | 7 | ||||||

| Illinois Environmental Protection Agency | Provisional Groundwater Remediation Objectives, Class I Groundwater | 0.2 | 0.4 | ||||||||

| Illinois Environmental Protection Agency | Provisional Groundwater Remediation Objectives, Class II Groundwater | 0.2 | 0.2 | ||||||||

| North Carolina Department of Environmental Quality | Interim Maximum Allowable Concentration | 1.0 | |||||||||

| New Jersey Department of Environmental Protection | Interim Specific Ground Water Quality Criterion | 0.01 | |||||||||

| Maine Department of Environmental Protection | Remedial Action Guidelines for Residential Groundwater | 0.06 | 0.1 | ||||||||

| Michigan Department of Environmental Quality | Groundwater Residential Generic Cleanup Criteria and Screening Levels | 0.12 | 0.089 | ||||||||

| Michigan Department of Environmental Quality | Groundwater Nonresidential Generic Cleanup Criteria and Screening Levels | 0.5 | 0.28 | ||||||||

| Texas Commission on Environmental Quality Texas Risk Reduction Program | Protective Concentration Levels for 16 PFAS for Several Different Exposure Scenarios (Groundwater) | ||||||||||

| Alaska Department of Environmental Conservation | Cleanup Levels | 0.4 | 0.4 | ||||||||

| SOIL (mg/kg) | |||||||||||

| U.S. EPA Region 4 | Residential Soil Screening Level | 6 | 16 | ||||||||

| Minnesota Pollution Control Agency | Industrial Soil Reference Value (.xlsx) | 14 | 13 | 500 | |||||||

| Minnesota Pollution Control Agency | Residential Soil Reference Value(.xlsx) | 2.1 | 2.1 | 77 | |||||||

| Minnesota Pollution Control Agency | Recreational Soil Reference Value(.xlsx) | 2.6 | 2.5 | 95 | |||||||

| Maine Department of Environmental Protection | Remedial Action Guidelines for different exposure scenarios | 11-82 | |||||||||

| Texas Commission on Environmental Quality Texas Risk Reduction Program | Protective Concentration Levels for 16 PFAS for Several Different Exposure Scenarios (Soil) | ||||||||||

| Alaska Department of Environmental Conservation | Cleanup Level, Arctic Zone | 2.2 | 2.2 | ||||||||

| Alaska Department of Environmental Conservation | Cleanup Level, Under 40' Zone | 1.6 | 1.6 | ||||||||

| Alaska Department of Environmental Conservation | Cleanup Level, Over 40' Zone | 1.3 | 1.3 | ||||||||

| Alaska Department of Environmental Conservation | Cleanup Level, Migration to Groundwater (MTGW) | 0.0030 | 0.0017 | ||||||||

| Table 2. Summary of PFAS Regulatory Criteria. Regulatory criteria for PFAS are still evolving relatively quickly. Please check the hyperlinked reference to confirm that the regulatory criteria listed in the table are up to date before using this information. Some states have PFAS regulatory values for groundwater as a result of consent agreements (e.g., both West Virginia and Ohio signed a consent agreement with DuPont listing 0.4 µg/L as a precautionary site-specific action level for PFOA). Other states (e.g., Delaware, New Hampshire, New York) have adopted U.S. EPA provisional health advisory levels for PFOS and PFOA in several water systems. Pennsylvania has investigated PFOS contamination associated with two contaminated wells identified through EPA Unregulated Contaminant Monitoring Rule program. Alabama has also addressed PFAS contamination on a site-specific basis. Alaska has conducted sampling and monitoring for PFAS at multiple sites. | |||||||||||

Sampling and Analytical Methods

Because PFAS are present in several common consumer items, care should be taken during sampling to eliminate contact with other potential sources of PFAS. Most standard operating procedures and work plans advise avoiding the use of polytetrafluoroethylene-based (e.g., Teflon) components including tubing and lined sample bottle caps. Some also instruct samplers not to wear waterproof jackets or other outerwear with a waterproof coating, and to avoid handling packaged foods that may contain fluorotelomer-based chemicals to increase non-stick properties. Due to the affinity of PFAS for the air-water interface and the wettability of glass, sample bottles are typically polypropylene or high-density polyethylene.

Most commercial laboratories use a modified version of U.S. EPA Method 537 for the analysis of PFAS in drinking water. This method consists of solid phase extraction and liquid chromatography with tandem mass spectrometry. Analytes include PFOS, PFOA, and typically 12 other PFAS (mostly perfluorocarboxylic acids and perfluorosulfonic acids) of varying carbon chain length. Specialty laboratories have modified this analytical method for matrices other than drinking water, to better recover shorter-chain compounds, or achieve lower detection limits.

Commercial laboratories that can quantify an even broader suite of PFAS (e.g., those known to be present in AFFF formulations and degrade to form PFOA and PFOS) are rare. An analytical method to detect several families of PFAS precursors[31]. There is also the Total Oxidizable Precursor (TOP) assay, a bulk measurement of precursors that can be oxidized to perfluorocarboxylates[32]. Other approaches to quantify the total amount of organic fluorine in water samples include particle induced gamma-ray emission (PIGE) and absorbable organic fluorine (AOF)[33].

The cost-effectiveness of high-resolution site characterization methods for PFAS is currently limited due to the lack of a reliable analytical method that can be used in the field as a screening method. Several research groups have attempted to design a field-ready mobile analytical method. For example, United Science LLC is developing ion selective electrodes to measure PFOS at ng/L levels[34]. Geosyntec Consultants and Eurofins Eaton Analytical are developing a mobile field unit for screening PFOS and other PFAS to ng/L levels[35].

Fate and Transport

The following summarize some key concepts for PFAS fate and transport:

- Sorption: Both PFOA and PFOS are anions at typical environmental pH values, but still exhibit strong interactions with solid-phase organic carbon. For this reason, the foc-Koc method for predicting sorption is generally appropriate[36], though this has not been confirmed for all PFAS. Interactions with mineral phases, particularly ferric oxide materials, may be important in low f foc materials[37][38]. At present, empirical site-specific sorption estimates are recommended to accurately predict PFAS mobility[37].

- Biotransformation: PFOS, PFOA, and analogous compounds of varying chain lengths are persistent in the environment and do not readily biodegrade. Polyfluorinated forms partially degrade in the environment[39][40], particularly if conditions (e.g., dissolved oxygen concentrations, pH) have been altered to treat co-contaminants[41]. However, degradation products are often more recalcitrant – degradable polyfluorinated forms are precursors for PFOA, PFOS and their homologs. In contrast, fungal degradation has been shown to result in lower production of perfluorocarboxylic acids[39].

- Other effects of microbes: Some microbes, in the presence of PFOA, aggregate and produce extracellular polymeric substances[42]. Microbes also facilitate PFAS leaching under methanogenic conditions common at municipal solid waste landfills[43]. Depending on the conditions, microbial activity may therefore enhance the mobility of compounds like PFOS and PFOA or hypothetically have the opposite effect by increasing sorption.

- Effect of co-contaminants and co-contaminant remediation strategies: Interactions between PFAS and non-aqueous phase liquids can retard PFAS migration[44]. TCE dechlorination can be inhibited by PFAS[45] and that inhibition depends both on PFAS structure and[46]. PFAS precursors degraded to form PFOA and other PFAS at a former fire-fighting training area at Ellsworth Air Force Base, where several remediation methods, including soil vapor extraction, groundwater pump and treat, bioventing, and oxygen infusion were used to treat co-contaminants[41].

Soil and Groundwater Remediation

Due to the chemical and thermal stability of PFAS and the complexity of PFAS mixtures, soil and groundwater remediation is challenging and costly. Research is still ongoing to develop effective remedial strategies.

For soil, it is common to evaluate several management options: 1) treatment and/or direct on-site reuse, 2) temporary on-site storage, and 3) off-site disposal to a soil processing or treatment facility, licensed landfill, or incinerator. Soil treatment products are commercially available to stabilize PFAS and decrease leaching. Criteria for stabilizing or treating soils prior to landfill disposal are highly site specific. Other technologies that have been considered for removing PFAS from soil include soil washing and incineration.

For groundwater, management options include the following: 1) in situ treatment, 2) ex situ treatment and/or reuse, aquifer reinjection, or discharge to surface water, stormwater, or sewer, 3) temporary on-site storage, and 4) off-site disposal to a hazardous waste treatment and disposal facility. The most common remediation approach is to use pump-and-treat with granular activated carbon followed by off-site incineration of the spent activated carbon. This technology has been used for years at full scale[47]. However, granular activated carbon has a relatively low capacity for PFAS particularly when shorter-chain compounds are present. Sorption capacity improvement tests have been conducted on various forms of granular and powdered activated carbon, ion exchange, and other sorbent materials and mixtures of clay, powdered activated carbon, and other sorbents[48].

Other methods for ex situ PFAS removal include high-pressure membrane treatment using nanofiltration or reverse osmosis. Membrane technologies at full-scale municipal water treatment facilities have effectively removed PFAS[47]. For typical environmental remediation applications, however, membrane treatment has a higher cost than activated carbon and effectiveness can be impaired by other groundwater contaminants[49]. Neutral PFAS, such as the perfluoroalkyl sulfonamides, may not be sufficiently removed[50].

PFAS Treatment Research

PFAS treatment research includes the following topics:

- PFAS Sequestration: Sorbents are being investigated with the long-term goal of using them in an in situ barrier as a low-cost, long-term treatment solution, combined with a method for periodically regenerating or renewing the emplaced sorbent material and treating waste streams on site using ex-situ chemical oxidation (ESTCP project 2423[51]). SERDP/ESTCP has also funded research (ESTCP project ER-2425) to test in situ injection of chemical coagulants (e.g., polyaluminum chloride, cationic polymers) to aid with sorption[52].

- Proof-of-Concept for Biological Treatment: Fungi have been used successfully to degrade PFAS under laboratory conditions[39][53], but are more difficult to maintain in situ. New work (ESTCP project ER-2422) is focused on the viability of packaging the PFAS-degrading enzymes from wood-rotting fungi into “vaults” (naturally-occurring particles found in a wide variety of microorganisms) and using bioaugmentation for in situ degradation[54][55].

- Advanced Oxidation Processes: Advanced oxidation processes for PFAS include electrochemical oxidation, photolysis, and photocatalysis[55]. Electrocatalytic and catalytic approaches using Ti/RuO2 and other mixed metal oxide anodes have been used to oxidize PFAS in the laboratory under a range of conditions (ESTCP project 2424[56]).

- In Situ Chemical Reduction: Methods being investigated include the use of zero-valent metals/bimetals (Pd/Fe, Mg, Pd/Mg) with clay interlayers and co-solvent assisted Vitamin B12 defluorination. One ongoing project (SERDP project ER-2426) focuses on PFOS, which is recalcitrant to many oxidation processes[57]. Reductive technologies could be used as a first step in remediating PFOS and other PFAS.

Summary

PFAS are present in the environment and pose several challenges. Perfluoroalkyl substances are highly stable and can biomagnify in wildlife. Health-based advisory levels are low, i.e., ng/L concentrations in groundwater and drinking water. As awareness of PFAS grows and regulatory criteria evolve, site managers are conducting site investigation, improving analytical techniques, and designing and operating remediation systems. SERDP/ESTCP-funded research aims to demonstrate effective treatment technologies for PFAS and improve technology cost-effectiveness.

References

- ^ 1.0 1.1 1.2 U.S. Environmental Protection Agency, 2014. Emerging Contaminants Fact Sheet – Perfluorooctane Sulfonate (PFOS) and Perfluorooctanoic Acid (PFOA). EPA 505-F-14-001. March Fact Sheet

- ^ Hansen, K.J., L.A. Clemen, M.E. Ellefson and H.O. Johnson, 2001. Compound-Specific, Quantitative Characterization of Organic Fluorochemicals in Biological Matrices. Environmental Science and Technology 35(4):766-770.

- ^ U.S. Environmental Protection Agency, 2018. Risk Management for Per- and Polyfluoroalkyl Substances (PFASs) under TSCA. https://www.epa.gov/assessing-and-managing-chemicals-under-tsca/risk-management-and-polyfluoroalkyl-substances-pfass

- ^ U.S. Environmental Protection Agency, 2000. EPA and 3M announce phase out of PFOS. News release dated Tuesday May 16. U.S. EPA PFOS Phase Out Announcement

- ^ Rich, N., 2016. The lawyer who became DuPont’s worst nightmare. The New York Times Magazine.

- ^ U.S. Environmental Protection Agency, 2018. Fact Sheet: 2010/2015 PFOA Stewardship Program. https://www.epa.gov/assessing-and-managing-chemicals-under-tsca/fact-sheet-20102015-pfoa-stewardship-program

- ^ SERDP/ESTCP website on Per- and Polyfluorinated Substances (PFASs). https://www.serdp-estcp.org/Featured-Initiatives/Per-and-Polyfluoroalkyl-Substances-PFASs

- ^ U.S. Environmental Protection Agency, 2016. Drinking water health advisories for PFOA and PFOS. U.S. EPA Water Health Advisories - PFOA and PFOS

- ^ California State Water Resources Control Board, 2019. PFAS Phased Investigation Approach. https://www.waterboards.ca.gov/pfas/docs/7_investigation_plan.pdf

- ^ Michigan, 2019. PFAS response. Taking Action, Protecting Michigan. Michigan PFAS Action Response Team (MPART).

- ^ 11.0 11.1 OECD, 2015. Working Towards a Global Emission Inventory of PFASs: Focus on PFCAs – Status Quo and the Way Forward. Paris: Environmental, Health and Safety, Environmental Directorate, OECD/UNEP Global PFC Group.

- ^ 12.0 12.1 12.2 12.3 Interstate Technology and Regulatory Council, 2018. Naming Conventions and Physical and Chemical Properties of Per- and Polyfluoroalkyl Substances (PFAS). https://pfas-1.itrcweb.org/wp-content/uploads/2018/03/pfas_fact_sheet_naming_conventions__3_16_18.pdf

- ^ 13.0 13.1 13.2 13.3 U.S. Environmental Protection Agency, 2017. Technical Fact Sheet: Perfluorooctane Sulfonate (PFOS) and Perfluorooctanoic Acid (PFOA). EPA 505-F-17-001.

- ^ Interstate Technology Regulatory Council, 2018. PFAS Fact Sheets: Environmental Fate and Transport, Table 3-1. https://pfas-1.itrcweb.org/wp-content/uploads/2018/05/ITRCPFASFactSheetFTPartitionTable3-1April18.xlsx

- ^ 15.0 15.1 15.2 Agency for Toxic Substances and Disease Registry, 2018. ToxGuideTM for Perfluoroalkyls. https://www.atsdr.cdc.gov/toxguides/toxguide-200.pdf

- ^ Young, C.J., Furdui, V.I., Franklin, J., Koerner, R.M., Muir, D.C. and Mabury, S.A., 2007. Perfluorinated acids in arctic snow: new evidence for atmospheric formation. Environmental Science & Technology, 41(10), 3455-3461. doi: 10.1021/es0626234

- ^ Conder, J.M., Hoke, R.A., Wolf, W.D., Russell, M.H. and Buck, R.C., 2008. Are PFCAs bioaccumulative? A critical review and comparison with regulatory criteria and persistent lipophilic compounds. Environmental Science & Technology, 42(4), 995-1003. doi: 10.1021/es070895g

- ^ Sinclair, E., Mayack, D.T., Roblee, K., Yamashita, N. and Kannan, K., 2006. Occurrence of perfluoroalkyl surfactants in water, fish, and birds from New York State. Archives of Environmental Contamination and Toxicology, 50(3), pp.398-410. doi: 10.1007/s00244-005-1188-z

- ^ Minnesota Department of Health, 2018. Media FAQ: Fish Consumption Advisory, PFOS and Lake Elmo Fish 2018. https://www.co.washington.mn.us/DocumentCenter/View/20895/FAQ-2018-Fish-Consumption-Advisory-NR

- ^ State of Michigan, PFAS Response, Taking Action, Protecting Michigan, 2019. https://www.michigan.gov/pfasresponse/0,9038,7-365-86512_88981_88982---,00.html

- ^ C8 Science Panel, 2012. C8 Probable Link Reports. http://www.c8sciencepanel.org/prob_link.html

- ^ Benbrahim-Tallaa, L., Lauby-Secretan, B. Loomis, D., Guyton, K.Z., Grosse, Y., Bouvard, F. El Ghissassi, V., Guha, N., Mattock, H., Straif, K., 2014. Carcinogenicity of perfluorooctanoic acid, tetrafluoroethylene, dichloromethane, 1,2-dichloropropane, and 1,3-propane sultone. The Lancet Oncology, 15 (9), 924-925. doi: 10.1016/S1470-2045(14)70316-X

- ^ International Agency for Research on Cancer (IARC), 2016. Monographs on the evaluation of carcinogenic risks to humans. Lists of Classifications, Volumes 1 to 116. List of Classifications.pdf

- ^ Interstate Technology and Regulatory Council, 2017. History and Use of Per- and Polyfluoroalkyl Substances (PFAS). https://pfas-1.itrcweb.org/wp-content/uploads/2017/11/pfas_fact_sheet_history_and_use__11_13_17.pdf

- ^ Krafft, M.P. and Riess, J.G., 2015. Selected physicochemical aspects of poly-and perfluoroalkylated substances relevant to performance, environment and sustainability - Part one. Chemosphere, 129, 4-19. doi: 10.1016/j.chemosphere.2014.08.039

- ^ Birnbaum, L.S. and Grandjean, P., 2015. Alternatives to PFAS: Perspectives on the Science. Environmental Health Perspectives, 123(5), A104-A105. doi: 10.1289/ehp.1509944

- ^ Houtz, E.F., 2013. Oxidative measurement of perfluoroalkyl acid precursors: Implications for urban runoff management and remediation of AFFF-contaminated groundwater and soil. Ph.D. Dissertation. Available online at http://escholarship.org/uc/item/4jq0v5qp

- ^ Lang, J.R., Allred, B.M., Peaslee, G.F., Field, J.A. and Barlaz, M.A., 2016. Release of Per-and Polyfluoroalkyl Substances (PFAS) from Carpet and Clothing in Model Anaerobic Landfill Reactors. Environmental Science & Technology, 50(10), 5024-5032. doi: 10.1021/acs.est.5b06237

- ^ Interstate Technology and Regulatory Council, 2018. Aqueous Film-Forming Foam (AFFF). https://pfas-1.itrcweb.org/wp-content/uploads/2019/03/pfas-fact-sheet-afff-10-3-18.pdf

- ^ Concawe, 2016. Environmental fate and effects of poly- and perfluoroalkyl substances (PFAS). Report no. 8/16. Report pdf

- ^ TerMaath, S., J. Field and C. Higgins, 2016. Per- and polyfluoroalkyl substances (PFAS): Analytical and characterization frontiers. Webinar Series

- ^ Houtz, E.F., Higgins, C.P., Field, J.A. and Sedlak, D.L., 2013. Persistence of perfluoroalkyl acid precursors in AFFF-impacted groundwater and soil. Environmental Science & Technology, 47(15), 8187-8195. doi: 10.1021/es4018877

- ^ Willach, S., Brauch, H.J. and Lange, F.T., 2016. Contribution of selected perfluoroalkyl and polyfluoroalkyl substances to the adsorbable organically bound fluorine in German rivers and in a highly contaminated groundwater. Chemosphere, 145, 342-350. doi:10.1016/j.chemosphere.2015.11.113

- ^ U.S. Environmental Protection Agency, 2015. Final report: field deployable PFCs sensors for contaminated soil screening. EPA contract number EPD14012. Report pdf

- ^ Deeb, R., Chambon, J., Haghani, A., and Eaton, A., 2016. Development and testing of an analytical method for real time measurement of polyfluoroalkyl and perfluoroalkyl substances (PFAS). Presented at the Battelle Chlorinated Conference, Palm Springs, CA.

- ^ Higgins, C.P., and Luthy, R.G., 2006. Sorption of perfluorinated surfactants on sediments. Environmental Science & Technology, 40(23), 7251-7256. doi: 10.1021/es061000n

- ^ 37.0 37.1 Ferrey, M.L., Wilson, J.T., Adair, C., Su, C., Fine, D.D., Liu, X. and Washington, J.W., 2012. Behavior and fate of PFOA and PFOS in sandy aquifer sediment. Groundwater Monitoring & Remediation, 32(4), 63-71. doi: 10.1111/j.1745-6592.2012.01395.x

- ^ Johnson, R.L., Anschutz, A.J., Smolen, J.M., Simcik, M.F. and Penn, R.L., 2007. The adsorption of perfluorooctane sulfonate onto sand, clay, and iron oxide surfaces. Journal of Chemical & Engineering Data, 52(4), 1165-1170. doi: 10.1021/je060285g

- ^ 39.0 39.1 39.2 Tseng, N., Wang, N., Szostek, B. and Mahendra, S., 2014. Biotransformation of 6: 2 fluorotelomer alcohol (6: 2 FTOH) by a wood-rotting fungus. Environmental Science & Technology, 48(7), 4012-4020. doi:10.1021/es4057483

- ^ Harding-Marjanovic, K.C., Houtz, E.F., Yi, S., Field, J.A., Sedlak, D.L. and Alvarez-Cohen, L., 2015. Aerobic biotransformation of fluorotelomer thioether amido sulfonate (Lodyne) in AFFF-amended microcosms. Environmental Science & Technology, 49(13), pp.7666-7674. doi: 10.1021/acs.est.5b01219

- ^ 41.0 41.1 McGuire, M.E., Schaefer, C., Richards, T., Backe, W.J., Field, J.A., Houtz, E., Sedlak, D.L., Guelfo, J.L., Wunsch, A. and Higgins, C.P., 2014. Evidence of remediation-induced alteration of subsurface poly-and perfluoroalkyl substance distribution at a former firefighter training area. Environmental Science & Technology, 48(12), 6644-6652. doi: 10.1021/es5006187

- ^ Weathers, T.S., Higgins, C.P. and Sharp, J.O., 2015. Enhanced biofilm production by a toluene-degrading rhodococcus observed after exposure to perfluoroalkyl acids. Environmental Science & Technology, 49(9), 5458-5466. doi: 10.1021/es5060034

- ^ Allred, B.M., Lang, J.R., Barlaz, M.A. and Field, J.A., 2015. Physical and biological release of poly-and perfluoroalkyl substances (PFAS) from municipal solid waste in anaerobic model landfill reactors. Environmental Science & Technology, 49(13), 7648-7656. doi: 10.1021/acs.est.5b01040

- ^ Guelfo, J. 2013. Subsurface fate and transport of poly- and perfluoroalkyl substances. Doctor of Philosophy Thesis, Colorado School of Mines. Thesis

- ^ Weathers, T.S., Harding-Marjanovic, K., Higgins, C.P., Alvarez-Cohen, L. and Sharp, J.O., 2015. Perfluoroalkyl acids inhibit reductive dechlorination of trichloroethene by repressing dehalococcoides. Environmental Science & Technology, 50(1), 240-248. doi: 10.1021/acs.est.5b04854

- ^ Harding-Marjanovic, K.C., Yi, S., Weathers, T.S., Sharp, J.O., Sedlak, D.L. and Alvarez-Cohen, L., 2016. Effects of Aqueous Film-Forming Foams (AFFFs) on Trichloroethene (TCE) Dechlorination by a Dehalococcoides mccartyi-Containing Microbial Community. Environmental Science & Technology, 50(7), 3352-3361. doi: 10.1021/acs.est.5b04773

- ^ 47.0 47.1 Appleman, T.D., Higgins, C.P., Quinones, O., Vanderford, B.J., Kolstad, C., Zeigler-Holady, J.C. and Dickenson, E.R., 2014. Treatment of poly-and perfluoroalkyl substances in US full-scale water treatment systems. Water Research, 51, 246-255. doi: 10.1016/j.watres.2013.10.067

- ^ Du, Z., Deng, S., Bei, Y., Huang, Q., Wang, B., Huang, J. and Yu, G., 2014. Adsorption behavior and mechanism of perfluorinated compounds on various adsorbents-A review. Journal of Hazardous Materials, 274, 443-454. doi:10.1016/j.jhazmat.2014.04.038

- ^ Department of the Navy (DON). 2015. Interim perfluorinated compounds (PFCs) guidance/frequently asked questions. FAQs

- ^ Steinle-Darling, E. and Reinhard, M., 2008. Nanofiltration for trace organic contaminant removal: structure, solution, and membrane fouling effects on the rejection of perfluorochemicals. Environmental Science & Technology, 42 (14), 5292–5297. doi: 10.1021/es703207s

- ^ Crimi, M. 2014. In situ treatment train for remediation of perfluoroalkyl contaminated groundwater: In situ chemical oxidation of sorbed contaminants (ISCO-SC), ER-2423. ER-2423

- ^ Simcik, M. (2014). Development of a novel approach for in situ remediation of PFC contaminated groundwater systems, ER-2425. ER-2425

- ^ Qingguo, J. H., 2013. Remediation of perfluoroalkyl contaminated aquifers using an In-situ two-layer barrier: laboratory batch and column study. ER-2127

- ^ Mahendra, S., 2014. Bioaugmentation with vaults: novel in situ remediation strategy for transformation of perfluoroalkyl compounds, SERDP, ER-2422. ER-2422

- ^ 55.0 55.1 Merino, N., Qu, Y., Deeb, R.A., Hawley, E.L., Hoffman, M.R and Mahendra, S., 2016. Degradation and removal methods for perfluoroalkyl and polyfluoroalkyl substances (PFAS) in water. Environmental Engineering Science, 33(9), 615-649. doi:10.1089/ees.2016.0233

- ^ Schaefer, C., 2014. Investigating electrocatalytic and catalytic approaches for in situ treatment of perfluoroalkyl contaminants in groundwater, ER-2424. ER-2424

- ^ Lee, L., 2014. Quantification of in situ chemical reductive defluorination (ISCRD) of perfluoroalkyl acids in groundwater impacted by AFFFs, ER-2426. ER-2426

See Also

Relevant Ongoing SERDP/ESTCP Projects:

- In situ treatment train for remediation of perfluoroalkyl contaminated groundwater: In situ chemical oxidation of sorbed contaminants (ISCO-SC). SERDP/ESTCP Project ER-2423

- Quantification of In Situ Chemical Reductive Defluorination (ISCRD) of perfluoroalkyl acids in groundwater impacted by AFFFs. SERDP/ESTCP Project ER-2426

- Bioaugmentation with vaults: Novel In Situ Remediation Strategy for Transformation of Perfluoroalkyl Compounds. SERDP/ESTCP Project ER-2422

- Investigating Electrocatalytic and Catalytic Approaches for In Situ Treatment of Perfluoroalkyl Contaminants in Groundwater. SERDP/ESTCP project ER-2424

- Development of a Novel Approach for In Situ Remediation of Pfc Contaminated Groundwater Systems. SERDP/ESTCP project ER-2425