Difference between revisions of "Sustainable Remediation"

(Created page with "Sustainable remediation involves evaluating remediation projects for their social, economic, and positive vs. negative environmental impacts. This key concept of incorporating...") |

(Created page with "Sustainable remediation involves evaluating remediation projects for their social, economic, and positive vs. negative environmental impacts. This key concept of incorporating...") |

(No difference)

| |

Revision as of 12:12, 27 April 2018

Sustainable remediation involves evaluating remediation projects for their social, economic, and positive vs. negative environmental impacts. This key concept of incorporating sustainability into remediation projects is beneficial because system level and holistic thinking helps to: (a) identify opportunities to improve the net benefit of the project, and (b) highlight specific negative project impacts that can be mitigated to limit their adverse socio-economic and environmental impacts. Project-level application of sustainable remediation is scalable and can involve a minimal approach on one project and can be more comprehensive on another project.

Related Article(s):

CONTRIBUTOR(S): Paul Favara

Key Resource(s):

- Sustainable Remediation White Paper: Integrating Sustainable Principles, Practices, and Metrics into Remediation Projects[1]

- Quantifying Life Cycle Environmental Footprints of Soil and Groundwater Remedies. ER-201127 Report[2]

- Green Remediation: Incorporating Sustainable Environmental Practices into Remediation of Contaminated Sites[3]

Introduction

Sustainable remediation has been an industry focus area since 2006, when a small group of individuals met to assess if the remediation industry could benefit from a more formal adoption of sustainability concepts[3][1][4][5]. Since that time, the topic has quickly launched into a key industry focus area. The main challenges in early sustainable remediation were how to define it and what the goals and outcomes would be. By 2011, three main variants of sustainable remediation were being applied to remediation projects around the world:

- Green Remediation. The U.S. Environmental Protection Agency (EPA) released its Green Remediation Primer, which focused on the green elements of sustainability-mainly the environmental attributes associated with remediation[3].

- Sustainable Remediation. The Sustainable Remediation Forum (SURF)[6] released its 2009 white paper addressing “Sustainable Remediation,” which is inclusive of social, environmental, and economic considerations[1].

- Green and Sustainable Remediation (GSR). In 2011, the Interstate Technology and Regulatory Council (ITRC) released its guidance on GSR[4]. The GSR phrase was a compromise between the members of the work groups that advocated green remediation and sustainable remediation.

Since sustainable remediation first became a topic of interest in the remediation industry, it has spread around the globe with SURF-like organizations in Canada, Brazil, Italy, United Kingdom, Taiwan, the Netherlands, Colombia, Japan, Australia, and New Zealand. Most of these organizations have their own guidance documents and white papers. In addition to the variable definitions and different geographies to consider, different organizations have their own definitions of sustainable remediation and internal processes and guidance on how to implement it.

Implementation Frameworks

There are a number of approaches that can be used to implement sustainable remediation. Frameworks underpin most of these approaches.

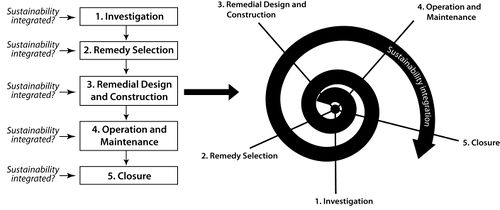

Sustainable remediation can be implemented in a phased approach, where sustainability is looked at only within the boundaries of the specific project phase (left side, Fig. 1). SURF provides a framework that advocates thinking holistically about sustainability and integration of sustainability through time; backward to take insights from previous project phases, and forward by thinking about future project outcomes and considering those sustainability impacts in the current project phase[7].

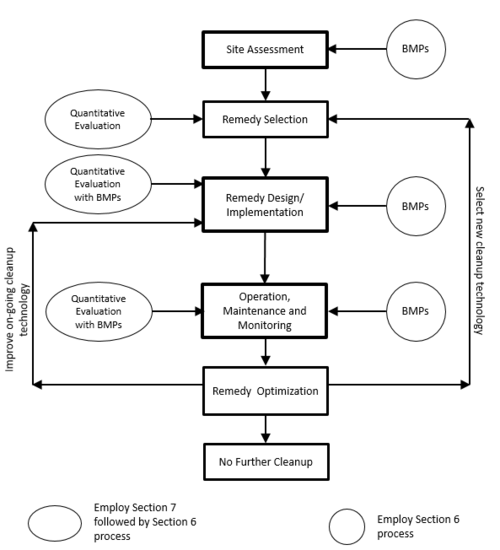

Another example framework is the American Society of Testing and Materials (ASTM) Greener Cleanup standard, which identifies opportunities to implement best management practices (BMPs) and quantitative assessments (e.g., footprint analysis or life-cycle assessment [LCA]) in different phases of the project life cycle (Fig. 2).

Metrics

Sustainable remediation often involves evaluation of several sustainability metrics that can be used to compare different remediation alternatives. There is a wide variety of metrics, but the following are often applied: carbon dioxide emissions, energy consumption, water use, material use, waste generation, and occupational risk. In a typical sustainable remediation project, these metrics are calculated by applying one of the sustainable remediation tools that are currently available. A comprehensive list and discussion of sustainable remediation metrics is presented in the SURF Metrics Toolbox[9].

Tools

There are a number of sustainable remediation tools used in the industry. The most commonly used ones include:

- Public domain footprint analysis tools such as SiteWise™[10], Sustainable Remediation Tool (SRT™)[11], and the U.S. EPA’s Spreadsheets for Environmental Footprint Analysis (SEFA)[12][13].

- Commercially available life-cycle assessment software such as SimaPro®[14].

- Best management practices (BMPs) that are published by SURF[9][4][15][5][8][16] and summaries by the U.S. EPA[17].

Footprint Analysis Tools and Life-Cycle Assessment (LCA) Tools

Footprint analysis and LCA tools are used to assess the environmental footprint of different remediation alternatives or design configurations by calculating environmental, risk, and sometimes social metrics.

Footprint analysis tools are primarily focused on estimating life cycle impacts associated with remediation project elements that contribute greenhouse gas emissions, nitrogen oxides, sulfur oxides, particulate matter, and energy. Some tools include other metrics such as occupational risk and resource service.

LCA tools are more comprehensive and consider hundreds of project inputs and outputs, including natural resources, materials, processes, chemicals, transportation, and waste management. The more robust datasets available in LCA software allow impacts to air, soil, and water to be considered and for those impacts to be reported in terms of their environmental impact. Example of impact categories addressed with LCA include global warming potential, smog (negative health and aesthetics), acidification (impacts on soil and water as well as buildings and monuments), eutrophication (nutrients discharged to surface water), fossil fuel depletion (measure of impacts related to using depleting fossil fuel resources), and carcinogens, non-carcinogens, and ecotoxicity (discharged to air, soil, and surface water).

The benefits and differences of footprint analysis and LCA tools is well documented[18][2][19].

Best Management Practices (BMPs)

Best management tools can be easily used by environmental professionals. Most of the tools are organized by topics and categories to allow practitioners to hone in on specific BMPs relevant for their project. BMPs can be integrated into a project faster than footprint analysis and LCA tools since calculations are typically not required. BMPs are typically evaluated through a series of screening steps to select the final BMPs for implementation. ASTM 2016[8] describes the example screening process.

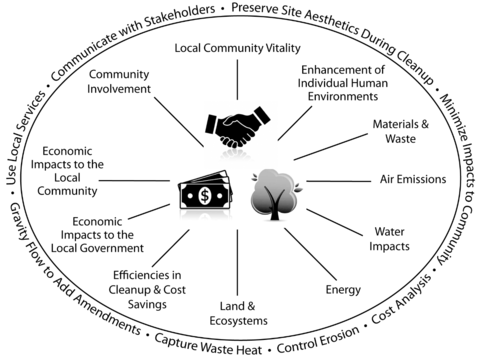

ASTM (2013)[5] developed a schematic that represents the relationship between the three main elements of sustainability (i.e., the so-called “triple bottom line” of sustainability-social, environmental, and economic domains) (Fig. 3). The standard EPA core elements or impact areas are represented as the “spokes of the wheel,” and example BMPs as the “wheel tread.”

The State of Sustainable Remediation

The remediation industry initially focused most of its energy into developing tools to help assess and implement sustainability into projects. A number of guidance documents and webinars exist to provide a resource for practitioners to learn more about sustainable remediation. Sustainable remediation is a featured topic in most remediation conferences. Customers also commonly use it as an evaluation criterion in selecting remediation service providers.

Despite sustainable remediation being a commonly accepted practice, there is still uncertainty within the remediation industry on how to best use it. As sustainable remediation is not a regulatory requirement, there is an inconsistency in how it has been deployed across the remediation industry. Questions from buyers of sustainable remediation services typically include:

- How is value demonstrated?

- Should metrics (e.g., greenhouse gas emissions and energy use) be tracked? If yes, should this be on a project or portfolio basis?

- How much extra will it cost to implement?

- How can organizational alignment and consistency be achieved by implementing this “voluntary” practice within a project, portfolio, or program?

Practitioners are implementing sustainable remediation into many projects, albeit to variable degrees using different approaches. Several of the main approaches used are described below:

Minimalist

Some project teams use a minimalist approach that may involve highlighting a project attribute as sustainable, or including some brainstorming recommendations for BMPs. When sustainable remediation first started, this was sometimes referred to as “green washing”, because it involved business as usual by saying something was sustainable. Minimalist approaches can be sustainable if they provide value and make the most sense for small projects that are repeated a number of times (e.g., small excavation or in situ bioremediation projects).

Best Management Practices (BMPs)

Some project teams complete BMP evaluations. These evaluations involve using BMP tools to identify potentially applicable BMPs that can be implemented in the project phase. This approach can be considered a top-down approach since a project phase is typically developed and then BMPs are screened for applicability. The ASTM Greener Cleanup Standard advocates tracking the implementation of BMPs after the cleanup phase and making the results available to the public. This allows the site owner to make a self-certification that the project was completed with the greener cleanup standard. Some site owners may consider this certification valuable (e.g., similar to LEED for buildings).

System Thinking

Some project teams will use sustainable remediation as an opportunity to think about the approach to remediation differently and underpin project planning to consider sustainable remediation throughout the project life cycle. This is sometimes referred to as “system thinking.” This approach involves including sustainability into all project processes. Instead of developing an approach and improving upon it, sustainability is the basis for idea development and the project approaches are built on a sustainability premise. System thinking can be thought of as a bottom-up approach and represents the best opportunity for sustainable remediation to be a game changer in how remediation technology is implemented, since it forces thinking about new ideas rather than simply using traditional approaches. System thinking also applies conservation, optimization, and minimization approaches to make them more sustainable.

The Future of Sustainable Remediation

To some practitioners, sustainable remediation is considered an already studied focus area offering limited returns for further investigation. However, there is a network of sustainable remediation organizations such as SURF in the US as well as other countries including Australia/New Zealand, Brazil, Canada, Italy, the Netherlands, Taiwan, and UK, and also the Network of Industrially Contaminated Lands in Europe (NICOLE), that continue to push the boundaries of sustainable remediation and present new ideas and approaches to implementing sustainable remediation. Examples include evaluating greener and more sustainable treatment reagents, focusing more on the social aspect of sustainable remediation, and integrating groundwater conservation into remediation projects.

References

- ^ 1.0 1.1 1.2 Ellis, D.E., Hadley, P.W., 2009. Sustainable remediation white paper: Integrating sustainable principles, practices, and metrics into remediation projects. Remediation Journal, 19(3), 5-114. doi: 10.1002/rem.20210

- ^ 2.0 2.1 ESTCP, 2013. Quantifying Life Cycle Environmental Footprints of Soil and Groundwater Remedies. ER-201127. Report pdf

- ^ 3.0 3.1 3.2 U.S. Environmental Protection Agency (USEPA), 2008. Green remediation: Incorporating sustainable environmental practices into remediation of contaminated sites. EPA 542-R-08-002. Report pdf

- ^ 4.0 4.1 4.2 Interstate Technology and Regulatory Council (ITRC), 2011. Green and sustainable remediation: A practical framework. GSR-2, ITRC Green and Sustainable Remediation Team, Washington, D.C. Report pdf

- ^ 5.0 5.1 5.2 5.3 American Society for Testing and Materials, 2013. Standard guide for integrating sustainable objectives into cleanup. ASTM E2876-13. doi: 10.1520/E2876

- ^ The Sustainable Remediation Forum (SURF), 2016. Sustainable Remediation Forum. SURF.

- ^ 7.0 7.1 Holland, K.S., Lewis, R.E., Tipton, K., Karnis, S., Dona, C., Petrovskis, E., Bull, L.P., Taege, D., Hook, C., 2011. Framework for integrating sustainability into remediation projects. Remediation Journal, 21(3), 7-38. doi: 10.1002/rem.20288

- ^ 8.0 8.1 8.2 American Society for Testing and Materials (ASTM), 2016. Standard guide for greener cleanups. ASTM E2893-16. doi:10.1520/E2893-16

- ^ 9.0 9.1 Butler, P.B., Larsen‐Hallock, L., Lewis, R., Glenn, C., Armstead, R., 2011. Metrics for integrating sustainability evaluations into remediation projects. Remediation Journal, 21(3), 81-87. doi: 10.1002/rem.20290

- ^ NAVFAC, 2016. SiteWise™ Tool - V3.1. Developed by the Department of the Navy, Army Corps of Engineers, & Battelle. Navy SiteWise™ Tool

- ^ Air Force Center for Engineering and the Environment, 2011. Sustainable Remediation Tool User Guide, Version 2.2. Report pdf

- ^ U.S. Environmental Protection Agency Spreadsheets for Environmental Footprint Analysis (SEFA). Website

- ^ U.S. Environmental Protection Agency, 2012. Methodology for Understanding and Reducing a Project’s Environmental Footprint. EPA 542-R-12-002. Report pdf

- ^ PRé, 2016. SimaPro. Putting the metrics behind sustainability. PRe Sustainability - SimPro Webpage (Last accessed on October 18, 2016).

- ^ US Army Corp of Engineers, 2012. Evaluation of consideration and incorporation of Green and Sustainable Remediation (GSR) practices in army environmental remediation. Report pdf

- ^ US Navy, 2016. Green and sustainable remediation best management practices. Technical Memorandum TM-NAVFAC-EXWC-EV-1601. Report pdf

- ^ U.S. Environmental Protection Agency, 2016. Best Management Practices for green remediation focus. Fact Sheets

- ^ Favara, P.J., Krieger, T.M., Boughton, B., Fisher, A.S., Bhargava, M., 2011. Guidance for performing footprint analyses and life‐cycle assessments for the remediation industry. Remediation Journal, 21(3), 39-79. doi: 10.1002/rem.20289

- ^ The Sustainable Remediation Forum (SURF), 2016. Tools and Calculators. Sustainable Remediation Tools

See Also

- ITRC Green and Sustainable Remediation Course Archive, 2016

- Network of Industrially Contaminated Lands in Europe (NICOLE)

- Sustainable Remediation Forum (SURF)

- Sustainable Remediation Forum (SURF) Green and Sustainable Remediation Resource Page

- Sustainable Remediation Forum (SURF) Tools and Calculators

- Sustainable Remediation Forum (SURF) Library Issue Papers

- Sustainable Remediation Forum (SURF) Affiliates

- Sustainable Sediment Remediation

- USEPA Green Remediation Focus

- USEPA Green and Sustainable Remediation Youtube Video

- US Navy Green and Sustainable Remediation

- Quantifying Life-Cycle Environmental Footprints of Soil and Groundwater Remedies