Difference between revisions of "User:Jhurley/sandbox"

(→Introduction) |

|||

| Line 18: | Line 18: | ||

==Introduction== | ==Introduction== | ||

| − | Supercritical water oxidation (SCWO) is an [[Wikipedia: Advanced oxidation process | advanced oxidation process]] that holds enormous potential for the treatment of a wide range of organic wastes, in particular concentrated wet wastes in slurries such as biosolids, sludges, agricultural wastes, chemical wastes with recalcitrant chemicals such as [[Perfluoroalkyl and Polyfluoroalkyl Substances (PFAS)| perfluoroalkyl and polyfluoroalkyl substances (PFAS)]], and many more. SCWO relies on the unique reactivity and transport properties that occur when an aqueous waste stream is brought above the critical point of water (374°C and 218 atm, or 704°F and 3200 psi, see phase diagram in Figure 1). [[Wikipedia: Supercritical fluid | Supercritical water]] is a dense single phase with transport properties similar to those of a gas, and solvent properties comparable to those of a non-polar solvent | + | Supercritical water oxidation (SCWO) is an [[Wikipedia: Advanced oxidation process | advanced oxidation process]] that holds enormous potential for the treatment of a wide range of organic wastes, in particular concentrated wet wastes in slurries such as biosolids, sludges, agricultural wastes, chemical wastes with recalcitrant chemicals such as [[Perfluoroalkyl and Polyfluoroalkyl Substances (PFAS)| perfluoroalkyl and polyfluoroalkyl substances (PFAS)]], and many more. SCWO relies on the unique reactivity and transport properties that occur when an aqueous waste stream is brought above the critical point of water (374°C and 218 atm, or 704°F and 3200 psi, see phase diagram in Figure 1). [[Wikipedia: Supercritical fluid | Supercritical water]] is a dense single phase with transport properties similar to those of a gas, and solvent properties comparable to those of a non-polar solvent<ref name="Tassaing2002">Tassaing, T., Danten, Y., and Besnard, M., 2002. Infrared spectroscopic study of hydrogen bonding in water at high temperature and pressure, Journal of Molecular Liquids, 101(1-3), pp. 149-158. [https://doi.org/10.1016/S0167-7322(02)00089-2 DOI: 10.1016/S0167-7322(02)00089-2]</ref>. Oxygen is fully soluble in supercritical water, resulting in extremely rapid and complete oxidation of all organics to carbon dioxide, clean water (that can be reused), and some non-leachable inorganic salts. |

| + | |||

| + | For SCWO to be economical, the heat from the oxidation reaction is recovered and used in part to heat the influent stream while the excess heat can be converted to electricity. Depending on the concentration of waste in the feedstock, SCWO reactors can be operated autothermally, i.e., no outside input of heat is required. Typical reaction times are in the order of 2-10 seconds, resulting in SCWO systems that are quite compact compared to other technologies (see Table 1). The process does not generate harmful by-products such as nitrogen oxides (NOx) or Sulfur oxides (SOx), carbon monoxide (CO), or odors | ||

| + | |||

| + | |||

Revision as of 17:13, 16 March 2021

Supercritical Water Oxidation (SCWO)

Supercritical water oxidation (SCWO) is a single step wet oxidation process that transforms organic matter into water, carbon dioxide and, depending on the waste undergoing treatment, an inert mineral solid residue. The process is highly effective and can treat a variety of wet wastes without dewatering. The SCWO technology allows for the complete destruction of persistent and toxic organic contaminants such as perfluoroalkyl and polyfluoroalkyl substances (PFAS), 1,4-dioxane, and many more.

Related Article(s):

Contributor(s): Kobe Nagar and Dr. Marc Deshusses

Key Resource(s):

- Treatment of municipal sewage sludge in supercritical water: A review[1].

- Supercritical Water Oxidation – Current Status of Full-scale Commercial Activity for Waste Destruction[2].

Introduction

Supercritical water oxidation (SCWO) is an advanced oxidation process that holds enormous potential for the treatment of a wide range of organic wastes, in particular concentrated wet wastes in slurries such as biosolids, sludges, agricultural wastes, chemical wastes with recalcitrant chemicals such as perfluoroalkyl and polyfluoroalkyl substances (PFAS), and many more. SCWO relies on the unique reactivity and transport properties that occur when an aqueous waste stream is brought above the critical point of water (374°C and 218 atm, or 704°F and 3200 psi, see phase diagram in Figure 1). Supercritical water is a dense single phase with transport properties similar to those of a gas, and solvent properties comparable to those of a non-polar solvent[3]. Oxygen is fully soluble in supercritical water, resulting in extremely rapid and complete oxidation of all organics to carbon dioxide, clean water (that can be reused), and some non-leachable inorganic salts.

For SCWO to be economical, the heat from the oxidation reaction is recovered and used in part to heat the influent stream while the excess heat can be converted to electricity. Depending on the concentration of waste in the feedstock, SCWO reactors can be operated autothermally, i.e., no outside input of heat is required. Typical reaction times are in the order of 2-10 seconds, resulting in SCWO systems that are quite compact compared to other technologies (see Table 1). The process does not generate harmful by-products such as nitrogen oxides (NOx) or Sulfur oxides (SOx), carbon monoxide (CO), or odors

Three technologies are well demonstrated for removal of PFAS from drinking water and non-potable groundwater (as described below):

- membrane filtration including reverse osmosis (RO) and nanofiltration (NF)

- granular activated carbon (GAC) and powdered activated carbon (PAC) adsorption

- anion exchange (IX)

However, these technologies are less demonstrated for removal of PFAS from more complex matrices such as wastewater and leachate. Site-specific considerations that affect the selection of optimum treatment technologies for a given site include water chemistry, required flow rate, treatment criteria, waste residual generation, residual disposal options, and operational complexity. Treatability studies with site water are highly recommended because every site has different factors that may affect engineering design for these technologies.

Membrane Filtration

Given their ability to remove dissolved contaminants at a molecular size level, RO and some NF membranes can be highly effective for PFAS removal. For RO systems (Figure 1), several studies have demonstrated effective removal of perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS) (see PFAS for nomenclature) from drinking water with removal rates well above 90%[4][5][6]. RO potable water reuse treatment systems implemented in California have also demonstrated effective PFOS and PFOA removal as reported by the Water Research Foundation (WRF)[7]. Analysis of permeate at both sites referenced by the WRF confirmed that short and long chain PFAS concentrations in the treated water were reduced to levels below test method reporting limits.

Full-scale studies using larger effective pore size NF membranes for PFAS removal are limited in number but are promising since NF systems are somewhat less costly than RO and may be nearly as effective in removing PFAS. Recent laboratory or pilot studies have shown good performance of NF membranes[8][9][10][11][12].

Although membrane RO and NF processes are generally capable of providing uniform removal rates relative to short and long chain PFAS compounds (see PFAS for nomenclature), other aspects of these treatment technologies are more challenging:

- Membranes must be flushed and cleaned periodically, such that overall water recovery rates (process water volumes consumed, wasted, and lost vs. treated water volumes produced) are much lower than those for GAC and IX processes. Membrane fouling can be slowed or avoided depending on operating conditions, membrane modifications, and feed modifications[13]. Typically, 70-90% of the water supplied into a membrane RO process is recoverable as treated water. The remaining 10-30% is reject containing approximately 4 to 8 times the initial PFAS concentration (depending on recovery rate).

- These cleaning and flushing processes create a continuous liquid waste stream, which periodically includes harsh membrane cleaning chemicals as well as a continuous flow of concentrated membrane reject chemicals (i.e., PFAS) that must be properly managed and disposed of. Management often includes further treatment to remove PFAS from the liquid waste.

- RO and NF systems are inherently more expensive and complicated systems to implement, operate, and maintain compared to adsorption processes. Treatment system operator certification and process monitoring requirements are correspondingly markedly higher for RO and NF than they are for GAC and IX.

- Water feed pressures required to drive flow through membrane RO and NF processes are considerably higher than those involved with GAC and IX processes. This results in reduced process efficiency and higher pumping and electrical operating costs.

- Membrane systems can also be subject to issues with irreversible membrane fouling, clogging, and scaling or other physical membrane damage and failures. Additional water pretreatment and higher levels of monitoring and maintenance are then required, further adding to the higher costs of such systems.

Activated Carbon Adsorption

Activated carbon is a form of carbon processed to have small pores that increase the surface area available for adsorption of constituents from water. Activated carbon is derived from many source materials, including coconut shells, wood, lignite, and bituminous coal. Different types of activated carbon base materials have varied adsorption characteristics such that some may be better suited to removing certain contaminant compounds than others. Results from laboratory testing, pilot evaluations, and full-scale system operations suggest that bituminous coal-based GAC is generally the best performing carbon for PFAS removal[14][15].

The removal efficiency of individual PFAS compounds using GAC is a function of both the PFAS functional group (carboxylic acid versus sulfonic acid) and also the perfluoro-carbon chain length[16][17](see PFAS for nomenclature):

- perfluoro-sulfonate acids (PFSAs) are more efficiently removed than perfluoro-carboxylic acids (PFCAs) of the same chain length

- long chain compounds of the same functional group are removed better than the shorter chains

Activated carbon may be applied in drinking water systems as GAC or PAC[18][19]. GAC has larger granules and is reusable, while PAC has much smaller granules and is not typically reused. PAC has most often been used as a temporary treatment because costs associated with disposal and replacement of the used PAC tend to preclude using it for long-term treatment. A typical GAC installation for a private drinking water well is shown in Figure 2. Contrary to PAC, GAC used to treat PFAS can be reactivated by the manufacturer, driving the PFAS from the GAC and into off-gas. The extracted gas is then treated with thermal oxidation (temperatures often 1200°C to 1400°C). The reactivated GAC is then brought back to the site and reused. Thus, GAC can ultimately be a destructive treatment technology.

Anion Exchange

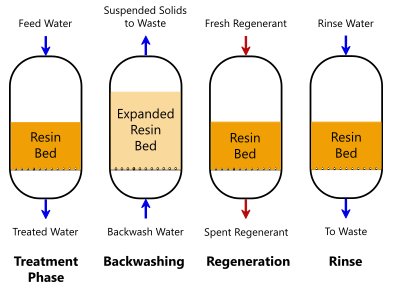

Anion exchange has also been demonstrated for the adsorption of PFAS, and published results note higher sorption per pound than GAC[16][20][21]. The higher capacity is believed to be due to combined hydrophobic and ion exchange adsorption mechanisms, whereas GAC mainly relies on hydrophobic attraction. Anion exchange resins can be highly selective, or they can also remove other contaminants based on design requirements and water chemistry. Resins have greater affinity for PFAS subgroup PFSA than for PFCA, and affinity increases with carbon chain length. Anion exchange resins are a viable alternative to GAC for ex situ treatment of PFAS anions, and several venders sell resins capable of removing PFAS. Resins available for treating PFAS include regenerable resins that can be used multiple times (Figure 3) and single-use resins that must be disposed or destroyed after use[20]. Regenerable resins generate a solvent and brine solution, which is distilled to recover the solvent prior to the brine being adsorbed onto a small quantity of GAC or resin for ultimate disposal. This use of one treatment technology (GAC, IX) to support another (RO) is sometimes referred to as a “treatment train” approach. Single-use resins can be more fully exhausted than regenerable resins can and may be a more cost-effective solution for low concentration PFAS contamination, while regenerable resins may be more cost effective for higher concentration contamination.

Developing PFAS Treatment Technologies

| Stage | Separation/Transfer | Destructive* |

|---|---|---|

| Developing | ||

| Maturing and Demonstrated |

||

| * There are several other destructive technologies such as alternative oxidants, and activation methods of oxidants, but for the purpose of this article, the main categories are presented here. | ||

Numerous separation and destructive technologies are in the developmental stages of bench-scale testing or limited field-scale demonstrations. Some of these are listed in Table 1:

Conclusions

The well established processes for removing PFAS from water all produce residuals that require management, and it is likely that newer processes under development will also produce some residuals. Often, it is the residuals that limit the usefulness of the process. For instance, RO and NF may currently provide the most complete treatment of water, but the production of a relatively high volume of PFAS-containing liquid reject (the portion of the liquid that retains the contaminants and is “rejected” from the process) limits their application. Often, a second treatment technology such as an adsorbent is required to support the main technology by concentrating or treating the residuals. As more testing and operational data on adsorbents are generated, it is becoming evident that no adsorbent technology outperforms the others in all cases. Whether GAC, ion exchange or another technology is the most technically efficient and cost effective long term option for a given site depends on influent water geochemistry and contaminant concentrations, treatment standards, co-contaminants, duration of treatment, and required flow rates. New generation adsorbents are rapidly being introduced into the market at “evaluation scale” which may provide advantages over commercially available adsorbents. Several newer technologies are being evaluated in the lab and in the field which include electro-oxidation, heat-activated persulfate, sonolysis, electrocoagulation, low temperature plasma, super critical water oxidation, and foam fractionation. These and other potential treatments for PFAS are still largely in the developmental stage. Several technologies show promise for improved management of PFAS sites. However, it is unlikely that a single technology will be adequate for full remediation at many sites. A multi-technology treatment train approach may be necessary for effective treatment of this complicated group of compounds.

References

- ^ Qian, L., Wang, S., Xu, D., Guo, Y., Tang, X., and Wang, L., 2016. Treatment of municipal sewage sludge in supercritical water: A review. Water Research, 89, pp. 118-131. DOI: 10.1016/j.watres.2015.11.047 nbsp; Free download from: ResearchGate

- ^ Marrone, P.A., 2013. Supercritical Water Oxidation – Current Status of Full-scale Commercial Activity for Waste Destruction. Journal of Supercritical Fluids, 79, pp. 283-288. DOI: 10.1016/j.supflu.2012.12.020 Author’s manuscript available from: US EPA

- ^ Tassaing, T., Danten, Y., and Besnard, M., 2002. Infrared spectroscopic study of hydrogen bonding in water at high temperature and pressure, Journal of Molecular Liquids, 101(1-3), pp. 149-158. DOI: 10.1016/S0167-7322(02)00089-2

- ^ Tang, C.Y., Fu, Q.S., Robertson, A.P., Criddle, C.S., and Leckie, J.O., 2006. Use of Reverse Osmosis Membranes to Remove Perfluorooctane Sulfonate (PFOS) from Semiconductor Wastewater. Environmental Science and Technology, 40(23), pp. 7343-7349. DOI: 10.1021/es060831q

- ^ Flores, C., Ventura, F., Martin-Alonso, J., and Caixach, J., 2013. Occurrence of perfluorooctane sulfonate (PFOS) and perfluorooctanoate (PFOA) in NE Spanish surface waters and their removal in a drinking water treatment plant that combines conventional and advanced treatments in parallel lines. Science of the Total environment, 461, 618-626. DOI: 10.1016/j.scitotenv.2013.05.026

- ^ Appleman, T.D., Higgins, C.P., Quiñones, O., Vanderford, B.J., Kolstad, C., Zeigler-Holady, J.C., and Dickenson, E.R., 2014. Treatment of poly- and perfluoroalkyl substances in US full-scale water treatment systems. Water Research, 51, pp. 246-255. DOI: 10.1016/j.watres.2013.10.067

- ^ Cite error: Invalid

<ref>tag; no text was provided for refs namedDickenson2016 - ^ Steinle-Darling, E., and Reinhard, M., 2008. Nanofiltration for Trace Organic Contaminant Removal: Structure, Solution, and Membrane Fouling Effects on the Rejection of Perfluorochemicals. Environmental Science and Technology, 42(14), pp. 5292-5297. DOI: 10.1021/es703207s Free download from: Academia.

- ^ Appleman, T.D., Dickenson, E.R., Bellona, C., and Higgins, C.P., 2013. Nanofiltration and granular activated carbon treatment of perfluoroalkyl acids. Journal of Hazardous Materials, 260, 740-746. DOI: 10.1016/j.jhazmat.2013.06.033

- ^ Soriano, Á., Gorri, D., and Urtiaga, A., 2017. Efficient treatment of perfluorohexanoic acid by nanofiltration followed by electrochemical degradation of the NF concentrate. Water Research, 112, 147-156. DOI: 10.1016/j.watres.2017.01.043 Author’s Manuscript.

- ^ Zeng, C., Tanaka, S., Suzuki, Y., Yukioka, S., and Fujii, S., 2017. Rejection of Trace Level Perfluorohexanoic Acid (PFHxA) in Pure Water by Loose Nanofiltration Membrane. Journal of Water and Environment Technology, 15(3), pp. 120-127. DOI: 10.2965/jwet.16-072 Free download from: J-STAGE

- ^ Wang, J., Wang, L., Xu, C., Zhi, R., Miao, R., Liang, T., Yue, X., Lv, Y. and Liu, T., 2018. Perfluorooctane sulfonate and perfluorobutane sulfonate removal from water by nanofiltration membrane: The roles of solute concentration, ionic strength, and macromolecular organic foulants. Chemical Engineering Journal, 332, pp. 787-797. DOI: 10.1016/j.cej.2017.09.061

- ^ Le Roux, I., Krieg, H.M., Yeates, C.A. and Breytenbach, J.C., 2005. Use of chitosan as an antifouling agent in a membrane bioreactor. Journal of Membrane Science, 248(1-2), pp. 127-136. DOI: 10.1016/j.memsci.2004.10.005

- ^ McNamara, J.D., Franco, R., Mimna, R., and Zappa, L., 2018. Comparison of Activated Carbons for Removal of Perfluorinated Compounds from Drinking Water. Journal‐American Water Works Association, 110(1), pp. E2-E14. DOI: 10.5942/jawwa.2018.110.0003

- ^ Westreich, P., Mimna, R., Brewer, J., and Forrester, F., 2018. The removal of short‐chain and long‐chain perfluoroalkyl acids and sulfonates via granular activated carbons: A comparative column study. Remediation Journal, 29(1), pp. 19-26. DOI: 10.1002/rem.21579

- ^ 16.0 16.1 McCleaf, P., Englund, S., Östlund, A., Lindegren, K., Wiberg, K., and Ahrens, L., 2017. Removal efficiency of multiple poly-and perfluoroalkyl substances (PFASs) in drinking water using granular activated carbon (GAC) and anion exchange (AE) column tests. Water Research, 120, pp. 77-87. DOI: 10.1016/j.watres.2017.04.057

- ^ Eschauzier, C., Beerendonk, E., Scholte-Veenendaal, P., and De Voogt, P., 2012. Impact of Treatment Processes on the Removal of Perfluoroalkyl Acids from the Drinking Water Production Chain. Environmental Science and Technology, 46(3), pp. 1708-1715. DOI: 10.1021/es201662b

- ^ Dudley, L.A., Arevalo, E.C., and Knappe, D.R., 2015. Removal of Perfluoroalkyl Substances by PAC Adsorption and Anion Exchange. Water Research Foundation Project #4344. Free download of Executive Summary from: Water Research Foundation (Public Plus account)

- ^ Qian, J., Shen, M., Wang, P., Wang, C., Li, K., Liu, J., Lu, B. and Tian, X., 2017. Perfluorooctane sulfonate adsorption on powder activated carbon: Effect of phosphate (P) competition, pH, and temperature. Chemosphere, 182, pp. 215-222. DOI: 10.1016/j.chemosphere.2017.05.033

- ^ 20.0 20.1 Senevirathna, S.T.M.L.D., Tanaka, S., Fujii, S., Kunacheva, C., Harada, H., Shivakoti, B.R., and Okamoto, R., 2010. A comparative study of adsorption of perfluorooctane sulfonate (PFOS) onto granular activated carbon, ion-exchange polymers and non-ion-exchange polymers. Chemosphere, 80(6), pp. 647-651. DOI: 10.1016/j.chemosphere.2010.04.053 Free download from: ResearchGate

- ^ Woodard, S., Berry, J., and Newman, B., 2017. Ion exchange resin for PFAS removal and pilot test comparison to GAC. Remediation Journal, 27(3), pp. 19-27. DOI: 10.1002/rem.21515

- ^ Guo, W., Huo, S., Feng, J., and Lu, X., 2017. Adsorption of perfluorooctane sulfonate (PFOS) on corn straw-derived biochar prepared at different pyrolytic temperatures. Journal of the Taiwan Institute of Chemical Engineers, 78, pp. 265-271. DOI: 10.1016/j.jtice.2017.06.013

- ^ Kupryianchyk, D., Hale, S.E., Breedveld, G.D., and Cornelissen, G., 2016. Treatment of sites contaminated with perfluorinated compounds using biochar amendment. Chemosphere, 142, pp. 35-40. DOI: 10.1016/j.chemosphere.2015.04.085 Free download from: ResearchGate

- ^ Inyang, M., and Dickenson, E.R., 2017. The use of carbon adsorbents for the removal of perfluoroalkyl acids from potable reuse systems. Chemosphere, 184, pp. 168-175. DOI: 10.1016/j.chemosphere.2017.05.161

- ^ Espana, V.A.A., Mallavarapu, M., and Naidu, R., 2015. Treatment technologies for aqueous perfluorooctanesulfonate (PFOS) and perfluorooctanoate (PFOA): A critical review with an emphasis on field testing. Environmental Technology and Innovation, 4, pp. 168-181. DOI: 10.1016/j.eti.2015.06.001 Free download from: ResearchGate

- ^ CETCO, 2019. FLUORO-SORB® Adsorbent (product sales brochure). Free download Fluoro-Sorb.pdf

- ^ Zhang, Q., Deng, S., Yu, G., and Huang, J., 2011. Removal of perfluorooctane sulfonate from aqueous solution by crosslinked chitosan beads: sorption kinetics and uptake mechanism. Bioresource Technology, 102(3), pp. 2265-2271. DOI: 10.1016/j.biortech.2010.10.040

- ^ Cao, F., Wang, L., Ren, X., and Sun, H., 2016. Synthesis of a perfluorooctanoic acid molecularly imprinted polymer for the selective removal of perfluorooctanoic acid in an aqueous environment. Journal of Applied Polymer Science, 133(15). DOI: 10.1002/app.43192

- ^ Hu, L., Li, Y., and Zhang, W., 2016. Characterization and application of surface-molecular-imprinted-polymer modified TiO2 nanotubes for removal of perfluorinated chemicals. Water Science and Technology, 74(6), pp. 1417-1425. DOI: 10.2166/wst.2016.321 Free access article.

- ^ Zhang, C., Tang, J., Peng, C., and Jin, M., 2016. Degradation of perfluorinated compounds in wastewater treatment plant effluents by electrochemical oxidation with Nano-ZnO coated electrodes. Journal of Molecular Liquids, 221, pp. 1145-1150. DOI: 10.1016/j.molliq.2016.06.093

- ^ Urtiaga, A., Fernández-González, C., Gómez-Lavín, S., and Ortiz, I., 2015. Kinetics of the electrochemical mineralization of perfluorooctanoic acid on ultrananocrystalline boron doped conductive diamond electrodes. Chemosphere, 129, pp. 20-26. DOI: 10.1016/j.chemosphere.2014.05.090 Free download from: Academia.edu

- ^ Schaefer, C.E., Choyke, S., Ferguson, P.L., Andaya, C., Burant, A., Maizel, A., Strathmann, T.J. and Higgins, C.P., 2018. Electrochemical Transformations of Perfluoroalkyl Acid (PFAA) Precursors and PFAAs in Groundwater Impacted with Aqueous Film Forming Foams. Environmental Science and Technology, 52(18), pp. 10689-10697. DOI: 10.1021/acs.est.8b02726

- ^ Park, S., Lee, L.S., Medina, V. F., Zull, A., and Waisner, S., 2016. Heat-activated persulfate oxidation of PFOA, 6: 2 fluorotelomer sulfonate, and PFOS under conditions suitable for in-situ groundwater remediation. Chemosphere, 145, pp. 376-383. DOI: 10.1016/j.chemosphere.2015.11.097

- ^ Lin, A.Y.C., Panchangam, S.C., Chang, C.Y., Hong, P.A., and Hsueh, H.F., 2012. Removal of perfluorooctanoic acid and perfluorooctane sulfonate via ozonation under alkaline condition. Journal of Hazardous Materials, 243, pp. 272-277. DOI: 10.1016/j.jhazmat.2012.10.029

- ^ Campbell, T., Hoffmann, M.R., 2015. Sonochemical degradation of perfluorinated surfactants: Power and multiple frequency effects. Separation and Purification Technology, 156(3), pp. 1019-1027. DOI: 10.1016/j.seppur.2015.09.053 Free download from: ResearchGate

- ^ Cheng, J., Vecitis, C.D., Park, H., Mader, B.T., Hoffmann, M.R., 2010. Sonochemical Degradation of Perfluorooctane Sulfonate (PFOS) and Perfluorooctanoate (PFOA) in Groundwater: Kinetic Effects of Matrix Inorganics. Environmental Science and Technology, 44(1), pp. 445-450. DOI: 10.1021/es902651g

- ^ Gole, V.L., Sierra-Alvarez, R., Peng, H., Giesy, J.P., Deymier, P., Keswani, M., 2018. Sono-chemical treatment of per- and poly-fluoroalkyl compounds in aqueous film-forming foams by use of a large-scale multi-transducer dual-frequency based acoustic reactor. Ultrasonics Sonochemistry, 45, pp. 213-222. DOI: 10.1016/j.ultsonch.2018.02.014 Open access article. Report.pdf

- ^ Gole, V.L., Fishgold, A., Sierra-Alvarez, R., Deymier, P., Keswani, M., 2018. Treatment of perfluorooctane sulfonic acid (PFOS) using a large-scale sonochemical reactor. Separation and Purification Technology, 194, pp. 104-110. DOI: 10.1016/j.seppur.2017.11.009

- ^ Cornelsen Ltd., 2015. PerfluorAd, PFC Water Treatment Solution (product sales site). Website

- ^ Wang, Y., Lin, H., Jin, F., Niu, J., Zhao, J., Bi, Y., and Li, Y., 2016. Electrocoagulation mechanism of perfluorooctanoate (PFOA) on a zinc anode: Influence of cathodes and anions. Science of the Total Environment, 557, pp. 542-550. DOI: 10.1016/j.scitotenv.2016.03.114

- ^ Horst, J., McDonough, J., Ross, I., Dickson, M., Miles, J., Hurst, J., and Storch, P., 2018. Water Treatment Technologies for PFAS: The Next Generation. Groundwater Monitoring and Remediation, 38(2), pp. 13-23. DOI: 10.1111/gwmr.12281

- ^ EPC Media Group Pty Ltd., 2017. OPEC systems delivers PFAS contamination breakthrough. Waste + Water Management Australia, 44(3), 26-27. DOI: 10.3316/informit.253699294687114 ISSN: 1838-7098

- ^ Stratton, G.R., Dai, F., Bellona, C.L., Holsen, T.M., Dickenson, E.R., and Mededovic Thagard, S., 2017. Plasma-Based Water Treatment: Efficient Transformation of Perfluoroalkyl Substances in Prepared Solutions and Contaminated Groundwater. Environmental Science and Technology, 51(3), pp. 1643-1648. DOI: 10.1021/acs.est.6b04215

- ^ Singh, R.K., Multari, N., Nau-Hix, C., Anderson, R.H., Richardson, S.D., Holsen, T.M. and Mededovic Thagard, S., 2019. Rapid Removal of Poly- and Perfluorinated Compounds from Investigation-Derived Waste (IDW) in a Pilot-Scale Plasma Reactor. Environmental Science and Technology, 53(19), pp. 11375-11382. DOI: 10.1021/acs.est.9b02964