Difference between revisions of "Direct Push (DP) Technology"

(Created page with "Direct push (DP) technology provides a subsurface sampling, logging, and investigation technique that is efficient for application in unconsolidated formations consisting prim...") |

(No difference)

|

Revision as of 01:18, 17 February 2017

Direct push (DP) technology provides a subsurface sampling, logging, and investigation technique that is efficient for application in unconsolidated formations consisting primarily of sand, silt, and clay with some gravel. DP machines advance sampling and logging tools into the subsurface using a percussion hammer and vehicle weight, sometimes to depths exceeding 100 ft. DP tools are not for use in consolidated rock like limestone, granite or gneiss.

Related Article(s):

CONTRIBUTOR(S): Wesley McCall, M.S., P.G. and Tom Christy, P.E.

Key Resource(s):

Introduction

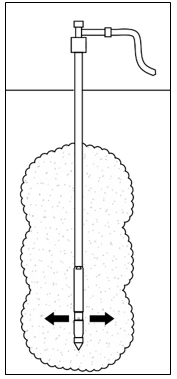

Direct push (DP) methods provide an alternative to traditional rotary drilling methods for investigation of soils and unconsolidated formations. Unlike rotary drilling methods which use rotation and removal of cuttings to advance tools into the subsurface, DP machines advance sampling and logging tools using a percussion hammer and vehicle weight (e.g. Figs 1, 2). Sampling and logging tools are advanced by rearrangement and compression of soil and sediment particles due to the high frequency percussive force of the hammer and weight of the machine when using the DP method. Essentially no drill cuttings are generated by the DP method. This minimizes generation of potential hazardous waste during contaminated site investigation and reduces the potential for worker exposure to hazardous contaminants relative to many traditional rotary drilling techniques.

Sampling depths of 50 to 100 feet (15 to 30 meters) and deeper can be achieved, depending on the local soils and geology. However, DP methods are not designed to penetrate rock (granite, gneiss, limestone, etc.) and may have difficulty penetrating dense tills, sediments rich in cobbles and boulders, or soils with thick caliché zones.

DP Machines

Direct push machines and tools are designed to investigate unconsolidated formations[1][2][3][4]. Early models of direct push machines were mounted in vans or conventional pickup trucks. Today, most of the DP machines are track mounted systems (Fig. 1). The large surface area of the tracks provides a lower ground pressure per unit area so that these machines are capable of moving across softer ground than typical wheeled vehicles. Small DP machines can squeeze through a 36-inch wide doorway to access building interiors and to sample in limited access spaces (e.g. tank farms). Larger machines are useful in probing difficult formations or when greater depths must be reached with larger tooling. However, larger tracked DP machines require a tractor-trailer truck for mobilization.

DP machines typically advance tools into the subsurface using a percussion hammer, vehicle weight, and hydraulics. However, some of the larger DP machines can be equipped with hollow stem augers or coring tools if required. Most DP machine units are track mounted, but some machines are installed in trucks and a few in specialized vehicles. Some units are equipped with a drop hammer for Standard Penetration Testing (SPT), rock coring system, sonic drilling capabilities, and soil anchors may be used to provide additional reaction force to advance any Cone Penetration Test (CPT) related tool.

DP Sampling

A variety of sampling tools have been developed to allow an investigator to obtain samples of soils, unconsolidated formations[1][2], and groundwater[1][5][6] (Fig. 2). DP methods also may be used to install monitoring wells[1][7] and soil vapor sampling devices[1][8]. Both single tube and dual tube methods are available for most sampling operations. Single tube methods are often quicker and easier to use, especially at shallow depths, but dual tube methods often provide samples of higher quality. To learn more about DP sampling, see: Direct Push Sampling.

DP Logging

Several DP logging tools have been developed since the late 1980s to assist with environmental and geological investigation of unconsolidated materials[1]. Many of these devices are used to perform high-resolution site characterizations[8], which allow for development of detailed conceptual site models and improved remedial actions. These logging tools are advanced into the subsurface without a pre-existing borehole or well and so are in intimate contact with the formation being studied. Several probes have been designed to measure physical properties of the formation such as soil strength ( CPT), electrical conductivity (EC), or permeability (Hydraulic Profiling Tool (HPT)). Other logging tools have been designed to detect the presence of certain groups of organic contaminants such as petroleum fuels ( Laser Induced Fluorescence (LIF), Optical Imaging Profiler (OIP)) (Fig. 3) or a variety of volatile organic compounds (Membrane Interface Probe (MIP)).To learn more about DP logging methods, see: Direct Push Logging.

Injection & Grouting

After sampling or logging operations are completed, each DP boring must be properly abandoned to prevent the possibility of movement of contaminants down hole or between zones in the subsurface[9]. Under most conditions bentonite or cement grouts are used for abandonment. For shallow borings in cohesive formations, it may be acceptable to simply pour bentonite chips down the open hole. The bentonite should be hydrated with clean water incrementally as the bentonite is added. However, for deeper borings and in formations prone to collapse, the borings should be grouted in a bottom-up fashion (Fig. 4). With some tools, it is possible to grout directly through the tool string as it is removed. For many dual-tube systems, the operator can lower a tremie tube down the outer casing to grout bottom-up. However, for some single-tube systems, it will be necessary to lower a tremie tube down the open boring, or in non-cohesive soils, install a second rod string with expendable point to inject grout into the borehole. DP methods also allow for injection of remediation fluids (sodium persulfate, etc.) at the desired location and depth interval. When it is preferable to conduct injections in a top-down manner some specialized, pressure activated injection probes may be applied (Fig. 5).

Conclusions

Direct push (DP) technology has provided many new tools and methods since the late 1980s that have improved the efficiency and reduced the cost of many geo-environmental investigations. Most DP machines are smaller and more compact than traditional rotary drilling equipment making it easier to access what were typically difficult to reach locations. The ability to quickly move equipment around a site and collect samples of soil or groundwater at the desired depths in unconsolidated materials has made it possible to implement expedited site assessment techniques such as those developed under the Triad model[10]. New machines, tools and logging methods are continually under development in the direct push industry.

References

- ^ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 McCall, W., Nielsen, D.M., Farrington, S.P., Christy, T.M., 2006. Use of Direct-Push Technologies in Environmental Site Characterization and Ground-Water Monitoring; in Practical Handbook of Environmental Site Characterization and Ground-Water Monitoring, 2nd Edition. Taylor & Francis Group, New York, NY. pgs. 345–471. doi: 10.1201/9781420032246.ch6

- ^ 2.0 2.1 American Society for Testing & Materials (ASTM) International, 2014. ASTM D6282/D6282-14. Standard guide for direct push soil sampling for environmental site characterizations. ASTM International, West Conshohocken, PA. doi: 10.1520/D6282_D6282M-14

- ^ U.S. Environmental Protection Agency, 2005. Expedited site assessment tools for underground storage tank sites, Chapter V, direct push technologies: a guide for regulators. EPA 510-B-97-001. Solid Waste and Emergency Response 5403G, Washington, D.C. EPA USTs site

- ^ Wilson, J.T., Ross, R.R. and Acree, S., 2005. Using direct‐push tools to map hydrostratigraphy and predict MTBE plume diving. Groundwater Monitoring & Remediation, 25(3), 93-102. doi: 10.1111/j.1745-6592.2005.00031.x

- ^ U.S. Environmental Protection Agency, 2005. Groundwater sampling and monitoring with direct push technologies. OSWER No. 9200.1-51. EPA 540/R-04-005. Office of Solid Waste and Emergency Response, Washington, D.C. Report pdf

- ^ American Society for Testing & Materials International, 2015. D6001. Standard guide for direct-push groundwater sampling for environmental site characterization. ASTM International, West Conshohocken, PA. doi: 10.1520/D6001-05R12

- ^ Interstate Technology & Regulatory Council (ITRC), 2006. The Use of direct push well technology for long-term environmental monitoring in groundwater investigations. Interstate Regulatory Council, Sampling, Characterization and Monitoring Team. SCM-2. Washington, D.C. Report pdf

- ^ 8.0 8.1 American Society for Testing & Materials International, 2015. D7663. Standard practice for active soil gas sampling in the vadose zone for vapor intrusion evaluations. ASTM International, West Conshohocken, PA. doi: 10.1520/D7663-12

- ^ Suthersan, S., Quinnan, J., Welty, N., 2015. The New ROI: Return on investigations by utilizing smart characterization methods. Groundwater Monitoring & Remediation, 35(3), 25-33. doi: 10.1111/gwmr.12118

- ^ Interstate Technology & Regulatory Council, 2003. Technical and regulatory guidance for the triad approach: A new paradigm for environmental project management (SCM-3). The Interstate Technology & Regulatory Council; Sampling, Characterization and Monitoring Team. Washington, D.C. Report pdf

See Also

- Drilling Rig Wikipedia Page

- Superfund Website

- Geoprobe Website for General Direct Push (DP) Equipment and Tools

- AMS Website for General Direct Push (DP) Equipment and Tools

- Solinst Website for Direct Push Tools

- Expedited Site Assessment Tools for Underground Storage Tank Sites: A Guide for Regulators

- Use of Dynamic Work Strategies Under a Triad Approach for Site Assessment and Cleanup – Technology Bulletin

- Characterization and Monitoring Technology Descriptions for Cleaning Up contaminated Sites

Videos

- Geoprobe Model 7822 Machine Features and Sampling Demonstration Youtube Video

- Geoprobe Model 54LT Features, Limited Access Machine Youtube Video

- Geoprobe Model 3230DT Machine, Features, DP, HSA, Wet Rotary, Air Rotary, Rock Coring Youtube Video

- Dual Tube Soil and Groundwater Sampling with DT22 Tools and 7822 Machine Youtube Video

- Advancing Hollow Stem Augers with Model 8040DT Geoprobe Machine Youtube Video

- Collecting Soil Samples with Dual Tube DT32 System Youtube Video